The 17th edition of ADIPEC has opened in Abu Dhabi with the focus this year on digitising the oilfield and conserving the future through the acceptance of technology

Held under the patronage of HH Sheikh Khalifa Bin Zayed Al Nahyan, President of the UAE and Ruler of Abu Dhabi, the opening ceremony saw speakers discuss the challenges and opportunities facing the oil and gas industry over the next 30 years.

Inaugurated by UAE National Security Adviser HH Sheikh Hazza Bin Zayed Al Nahyan, ADIPEC 2014 has been predicted to become the largest in the show’s history, with the four-day show hosting 18,000 exhibitors and 20 international pavilions.

Speakers over the four days of the event will include Sultan Ahmed Al Jaber, CEO - energy at Mubadala; Abdulla Naseer AlSuwaidi, director general of ADNOC; and Al Khalifa Al Shamsi, conference chairman of ADIPEC 2014, who will speak about ADIPEC’s journey since its first edition in 1984 and the role the event has played in shaping the oil and gas industry today.

UAE minister of energy HE Suhail Mohamed Al Mazrouei said that it was likely that ADIPEC had grown to become the world’s largest oil and gas conference gathering and the second largest oil and gas exhibition.

“The increasing number of participants indicate the importance of the event in linking the different oil and gas industry stakeholders together to discuss and exhibit the solutions to the challenges we face,” Al Mazrouei remarked.

Speaking on the first day of the event, theoretical physicist Michio Kaku said that the digitisation of oilfields would help save fuel resources.

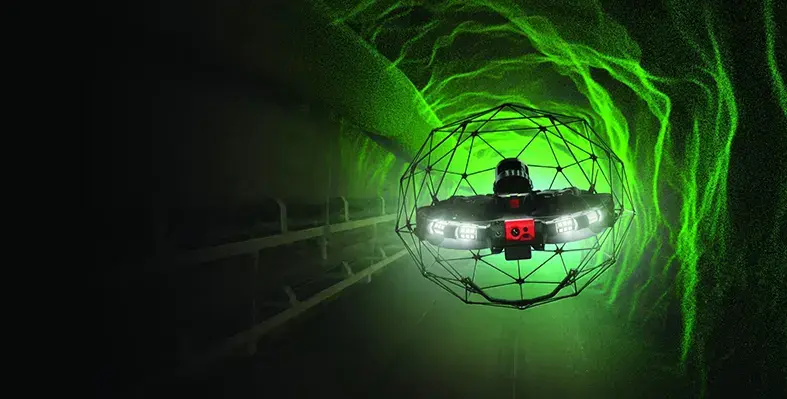

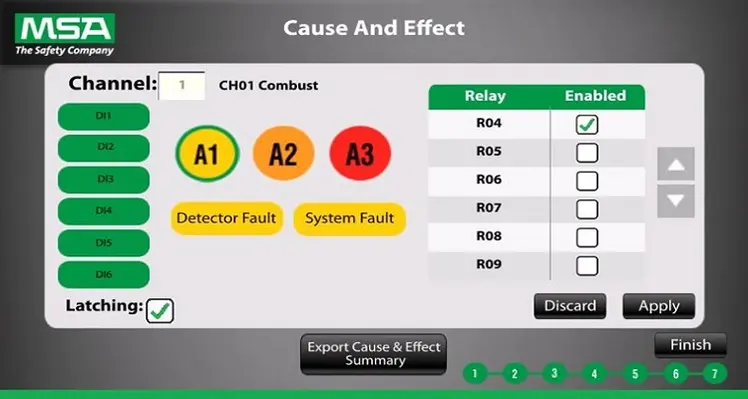

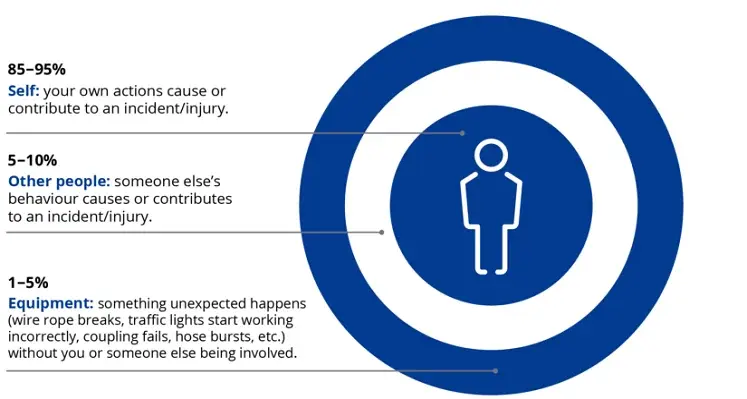

“Oil and gas companies will have to adopt to technical enhancement for better production and efficient manpower,” he said, before providing various instances where technology could potentially go a long way to minimising risks in oilfields and for personnel.

Kaku said that in the future, technology would enable workers from oilfields in various countries to connect via a universal translator with the use of embedded contact lenses. Specially made for the oil and gas sector, the lenses would be able to show blueprints of oil or gas fields, as well as provide instructions and diagrams.

The Henry Semat Professor of Theoretical Physics at the City College of New York said that while many oil companies did not see as accessible upcoming technical advances, the future would see many firms use computerised wallpaper to access data.

Kaku theorised that while hydraulic fracking was an efficient way to release hydrocarbon from the ground, dangerous effects lie in the creation of earthquakes, citing examples from Texas and areas where hydraulic fracking is common place. In order to lessen the downside, he suggested that carbon dioxide be injected into the ground to release oil and gas. In this way, carbon dioxide released to the upper atmosphere could sent back to the ground and conservation could be achieved.

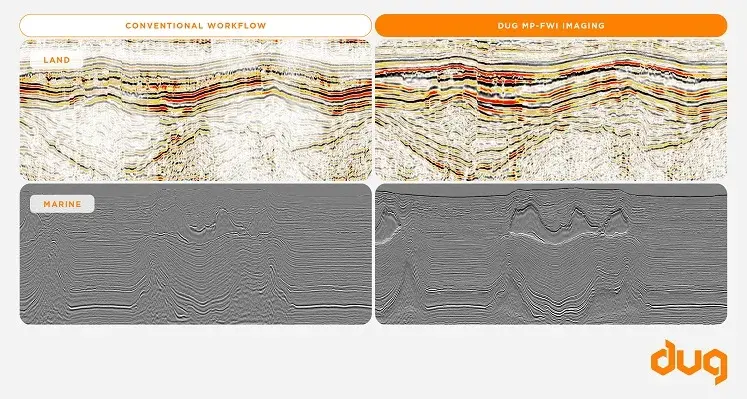

Kaku also said that increased instances of 3D modelling had helped engineers locate oil spills within the ground and advised more companies to accept this model in order to save fuel.

The opening ceremony of ADIPEC 2014 was followed by an international ministerial session attended by delegates from UAE, Kuwait, the UK and OPEC. The session covered the technologies needed by the oil and gas sector to fulfil the demands of the ever-increasing global population.

Al Mazrouei remarked, “The vision of UAE since the beginning was about looking into the future. We have forged partnership to express the development of the energy sector in the Middle East. In developing oil, we are also looking for more gas avenues, both for local consumption and exports.

“The challenge is to create local content or the workforce to help achieve additional targets.”

In regards to creating a larger local workforce in the country, Al Mazrouei said that Emiratis were playing an integral part in international companies, but added that he would like to see more local content created.

Kuwait’s minister of oil, Ali Saleh Al Omair, said, “Kuwait has many oil and gas projects in the pipeline, however, there is a need to educate and create engineers to actually come and work at our companies.”

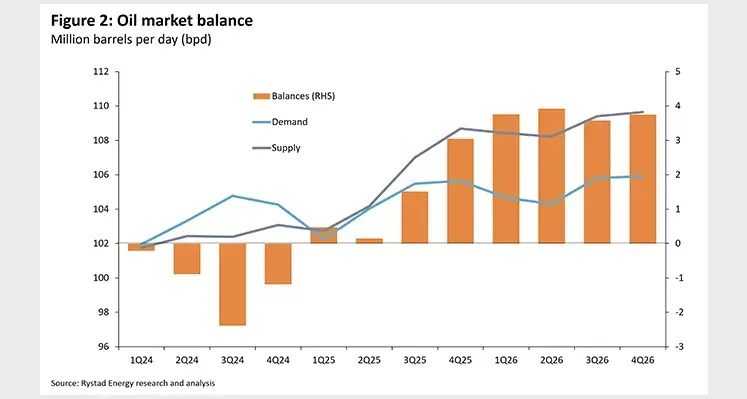

Al Omair added that the recent drop in oil prices was not threatening, but it could lead to lower levels of investment and lower supplies of exports. He added that the country had been looking at downstream projects and was considering a shift towards the production of cleaner energy.

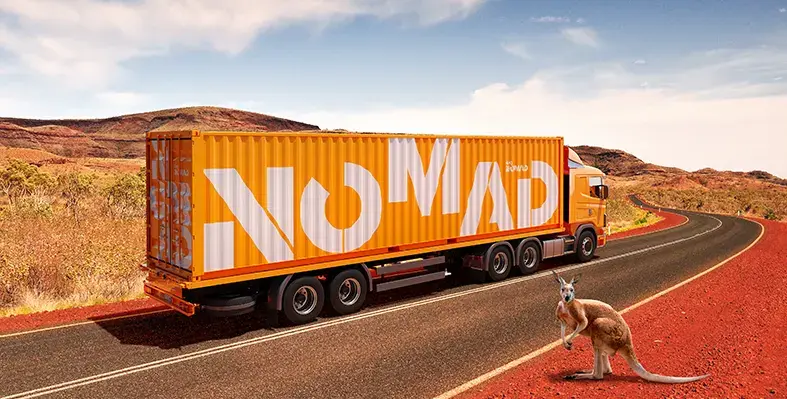

The recently introduced Nomad 40 takes this further, providing up to 1 megawatt of IT heat rejection and supporting more than 1,000 NVIDIA H200 GPUs or 92,000 CPU cores in a mobile, modular form. Both systems are engineered to operate in any environment – including the hot, arid conditions common across the Middle East – thanks to the integrated immersion-cooling system that shields hardware from dust and oxidation. This makes Nomad uniquely capable of delivering scalable compute power on demand in places where traditional air-cooled systems often struggle with efficiency and reliability.

The recently introduced Nomad 40 takes this further, providing up to 1 megawatt of IT heat rejection and supporting more than 1,000 NVIDIA H200 GPUs or 92,000 CPU cores in a mobile, modular form. Both systems are engineered to operate in any environment – including the hot, arid conditions common across the Middle East – thanks to the integrated immersion-cooling system that shields hardware from dust and oxidation. This makes Nomad uniquely capable of delivering scalable compute power on demand in places where traditional air-cooled systems often struggle with efficiency and reliability.