Oil and gas operations in the Middle East span harsh deserts, sprawling refineries and high-risk offshore environments. (Image source: Adobe Stock)

In the oil and gas industry, where every second counts and every decision impacts profitability and safety, robust security is not just a luxury – it's a necessity

From protecting critical assets to safeguarding human lives, security systems must meet the highest standards of reliability and performance.

Pelco, a leader in video security, is uniquely positioned to address the challenges faced by oil and gas companies in the Middle East, offering a fresh perspective on how to optimise security systems seamlessly. With our upcoming online event, we invite you to explore how Pelco can help tackle worker safety, asset protection and operational efficiency in this complex industry.

Addressing oil and gas challenges head-on

Oil and gas operations in the Middle East span harsh deserts, sprawling refineries and high-risk offshore environments. Physical, environmental and digital threats are converging, and security systems must evolve to meet these overlapping demands. Our upcoming online event will focus on three critical areas where Pelco's expertise can make a difference:

1. Improve worker safety and HSE compliance

Ensuring worker safety is both a moral responsibility and a regulatory imperative. Health, Safety and Environmental (HSE) compliance is a top priority for oil and gas operations. Pelco's advanced portfolio is designed to help you meet these standards.

Edge-based analytics and intelligent video security can be valuable tools in supporting site safety. These systems can help detect safety incidents, such as slips or falls, especially in areas where oily surfaces, heat or dust create additional hazards. When incidents occur in remote areas, automated detection can prompt faster intervention, thereby closing the gap between the event and the response.

Personal Protective Equipment (PPE) compliance is another key safety concern. High temperatures in the Middle East can lead to discomfort, and in some cases, workers may be tempted to remove protective gear, such as hard hats or vests, for temporary relief. In this case, AI-enabled video analytics can help identify instances of non-compliance, enabling safety teams to address the issue before it becomes a liability.

Zone-based behavioural analytics can help detect when someone enters a restricted or hazardous area or remains in a dangerous zone longer than necessary. For example, loitering detection near flare stacks or storage tanks can support situational awareness and proactive incident mitigation.

2. Improve security and asset protection

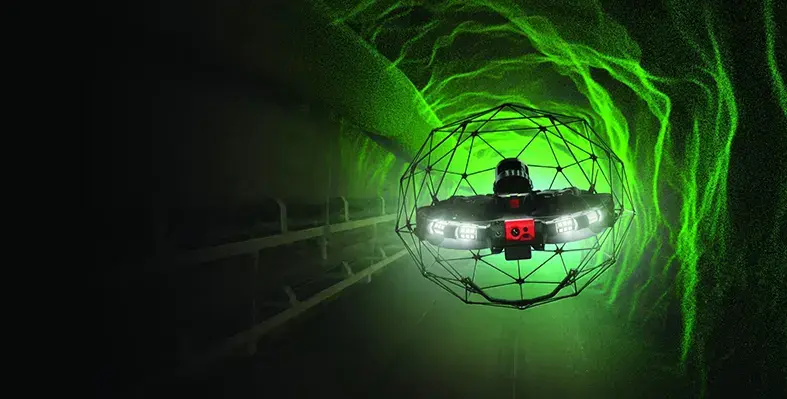

From refineries in the desert to offshore rigs in corrosive marine environments, your assets operate under pressure, so your security systems must withstand these harsh conditions. In areas where explosive gases or dust particles may be present, even basic equipment can pose risks. That’s why choosing video solutions built for hazardous environments is critical.

ExSite Enhanced cameras, featuring 316L stainless steel construction and certifications such as ATEX and IECEx, are designed for use in hazardous atmospheres. Whether it’s observing pipeline manifolds, wellheads or chemical storage areas, these systems deliver dependable performance in high-risk environments. In corrosive coastal locations, such as LNG terminals or offshore rigs, Pelco’s anti-corrosion models withstand salt spray, humidity and chemical exposure without compromising visibility.

For perimeter defence, long-range Silent Sentinel cameras give security teams early warning of approaching threats, detecting vehicles, vessels or drones from kilometres away in fog, darkness or dust. These systems are especially valuable for remote desert pipelines or unstaffed offshore installations, where rapid detection is critical to prevent disruptions.

3. Minimise downtime and maximise uptime

Every minute of downtime impacts revenue. For oil and gas operations, the cost of unplanned outages is measured in millions of dollars. With Pelco, your video security can become an operational asset.

Radiometric thermal cameras can detect overheating in transformers, compressors and electrical panels, allowing teams to take action before equipment failure occurs. At the same time, Pelco’s camera image health analytics help ensure your video infrastructure is always performing at its best. Our cameras automatically detect issues such as lens obstructions, misalignment or tampering, reducing the need for manual inspections and helping ensure your security coverage is always clear, optimised and ready when it matters most.

Join us to discover the Pelco advantage

We invite you to join our upcoming online event, where industry leaders and Pelco experts will dive deeper into these challenges and solutions. Together, we'll explore how Pelco can be the missing ingredient to supercharge your security and drive operational excellence in the Middle East oil and gas sector.

Don't miss this opportunity to gain actionable insights and position your operations for success. Register now and discover how Pelco can transform your approach to security.