In The Spotlight

The platform enables energy companies to harness AI-powered analytics to enhance their operations. (Image source: Adobe Stock)

AVEVA to showcase CONNECT platform at ADIPEC 2025

AVEVA, a global leader in industrial software, will showcase CONNECT, its AI-powered industrial intelligence platform, at ADIPEC 2025

AVEVA will demonstrate the power of CONNECT through augmented and virtual reality, highlighting how the platform supports every stage of the industrial lifecycle, from design and build, to operate, maintain, and optimise. The platform enables energy companies to harness AI-powered analytics for smarter and more sustainable business operations.

As the UAE accelerates its transition to a low-carbon economy and diversifies its energy mix, national initiatives such as the UAE Net Zero 2050 Strategy highlight the country’s commitment to sustainable growth and emission reduction. Aligned with these strategic ambitions, AVEVA provides energy companies with end-to-end industrial software solutions that seamlessly integrate engineering, operations, and performance, enabling them to enhance project execution, improve asset reliability, and drive measurable progress toward net-zero objectives.

Jesus Hernandez, SVP of EMEA, AVEVA said, “As the energy industry shifts towards a more sustainable future, our technologies ranging from digital twins to AI-driven analytics, are helping companies optimise operations, enhance asset reliability, and drive progress towards net-zero goals. We look forward to meeting regional customers and partners at ADIPEC and demonstrate how our solutions can support in navigating this complex transition to strengthen performance and organisational agility."

“The energy sector in the region is grappling with many challenges, from managing complex project execution and improving CAPEX efficiency to reducing unplanned downtime and addressing operational inefficiencies. There is a growing urgency around sustainability targets, particularly in emissions tracking and reporting. At ADIPEC, we will highlight how Industrial Intelligence-as-a-Service can help organisations across the Middle East unlock efficiency, sustainability, and growth by combining the power of AI, data, and human expertise,” said Nayef Bou Chaaya, AVEVA vice president, Middle East, Africa and Turkey.

AVEVA will be at Hall 4, Stand 4410

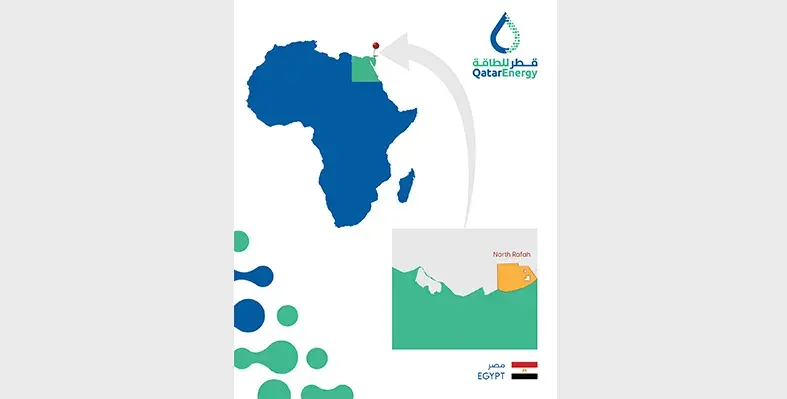

QatarEnergy acquires stake in Egypt offshore concession

QatarEnergy has acquired a 40% stake in the North Rafah block, offshore Egypt

The transaction was recently approved by the government of Egypt, with Eni retaining the remaining 60% interest as operator.

The North Rafah offshore block is located in the Mediterranean Sea, off the northeastern coast of Egypt. It spans nearly 3,000 sq kms in water depths of up to 450 m.

The announcement follows hard on the heels of the acquisition earlier this month of QatarEnergy’s 27% participating interest in the North Cleopatra block offshore Egypt, operated by Shell. It reflects the company’s push to expand upstream exploration activities globally, with maximising value from upstream being one of QatarEnergy’s five key strategic pillars in its vision to be one of the best energy companies in the world. Over the past few months QatarEnergy has acquired exploration licences in the Republic of Congo, Algeria and Namibia.

His Excellency Saad Sherida Al-Kaabi, the Minister of State for Energy Affairs, the president and CEO of QatarEnergy, said, "We are pleased with our new position in the North Rafah offshore block, which further strengthens our presence in Egypt and marks another important step in advancing our ambitious international exploration strategy."

ADIPEC 2025 to have strengthened AI and low-carbon focus

Christopher Hudson, president of dmg events, discusses what we can look forward to at ADIPEC this year

How is ADIPEC, as a leading energy event, responding to the major shifts being seen across the global energy sector?

Energy is one of the world’s most dynamic and rapidly evolving sectors. According to the International Energy Agency (IEA), global energy demand rose by 2.2% last year, outpacing the average annual increase of 1.3% recorded over the last decade. At the same time, the global population is projected to reach 9.8bn by 2050, with over 750mn people still lacking access to electricity, and more than 2.1bn people remain without access to clean cooking. These figures underscore both the scale of the challenge and the opportunity before us.

In this context, ADIPEC 2025 is being held under the theme of ‘Energy. Intelligence. Impact’. It reflects a simple but powerful truth: meeting the world’s growing need for secure, affordable and sustainable energy will depend on how intelligently we harness every resource to deliver meaningful results for economies and communities alike.

At its core, the theme recognises that intelligence – both human and artificial – is transforming the way energy is produced, managed, and consumed. From AI-driven optimisation and digital integration to advances in hydrogen, LNG, and decarbonisation, intelligent innovation is reshaping the global energy landscape. ADIPEC serves as the meeting point for these forces, where ideas translate into action and impact can be measured in investment, policy, and progress.

As the organiser of ADIPEC, we work closely with governments and industry to ensure our event reflects these realities. ADIPEC, at its core, is designed to bring energy, intelligence, and innovation together, turning dialogue into delivery, and ambition into tangible progress.

Artificial intelligence (AI) has a big focus at ADIPEC this year. How is AI impacting the energy sector and how is ADIPEC helping to steer that impact positively?

On the back of rising AI integration, data centres' electricity consumption is projected to double by 2030, rising from 415 TWh to 945 TWh. At the same time, the World Economic Forum has estimated that AI can improve energy efficiency by up to 60% in certain applications, while the IEA says that AI-optimised energy systems can increase production efficiency by up to 20%. The complex trade-off between AI’s energy demand and energy production/savings, presents the energy sector with a unique opportunity to accelerate the shift toward cleaner energy sources while improving energy system productivity.

To harness AI’s potential sustainably, the industry must invest in energy-efficient infrastructure, prioritise low-impact models, and shift workloads to low-emissions data centres, like those powered by solar energy or small modular reactors. Simultaneously, AI can be used to optimise its own energy use, such as scheduling tasks based on grid carbon intensity.

Responding to the opportunities and challenges presented by AI, we have expanded our AI Zone into five experiential areas showcasing how AI is transforming systems, people, and infrastructure. Our AI Zone, which is nearly 40% bigger this year than last year, will also feature many leading AI companies, including Microsoft, Infosys, IBM, AIQ, Honeywell, Cognite, SUPCON, Geminus AI, and Gecko Robotics, among its 40-some exhibitors.

Alongside this, more than 80 conference sessions are dedicated to the AI–energy nexus, from predictive analytics to governance frameworks. Some of the already confirmed speakers include: Dr Najwa Aaraj, CEO, TII; Dr. Ahmed Mohamed Alebri, CEO, ADNOC Sour Gas; Patrick Bangert, VP& Chief of AI, Oxy; and Michael Sonderby, CEO, SteerAI.

With our timely AI-focused conference and exhibition offerings, ADIPEC will explore how AI transforms the global energy system for more secure, inclusive and sustainable outcomes.

What impact do you hope ADIPEC 2025 to have on the world’s energy sector and its ongoing transformation?

ADIPEC 2025 offers a moment for industry leaders to focus on collective results, advancing secure, sustainable, and affordable energy that meets the needs of a growing global population.

One timely outcome that we hope ADIPEC helps advance for the global energy sector is enabling additional secure energy supply. Energy security and energy access for key industries, emerging markets, and communities are foundational for growth and development, supporting the livelihoods of billions and unlocking new avenues for innovation. But the energy industry is not immune to uncertainty, and today we find ourselves facing a multitude of competing priorities.

If the industry is to deliver on its mounting responsibilities and evolve to meet the needs of a world in perpetual change, it requires clarity and realism. While the necessity of decarbonisation is unquestionable and the appetite for energy has only increased, balancing these two realities cannot devolve into a debate between new and old, clean and carbon. Instead, we must come to terms with the complexity of modern demand and respond with pragmatism, using every tool and resource at our disposal to ensure the modern energy mix works for all. The answer that is becoming more obvious to energy leaders is to shift away from an energy transition towards energy addition, where our growing need for secure energy supply is met both by hydrocarbon energy and additional lower-carbon energy sources.

By convening all segments of the energy sector, including government, technology, finance, shipping, and infrastructure, ADIPEC facilitates the alignment, collaboration, and momentum the global energy sector needs to unlock finance and bring more energy online.

ADIPEC launched a new co-located Low Carbon & Chemicals Expo this year. What does that exhibition feature include and why is it timely?

Reflecting the industry’s transition towards a high-growth, lower-carbon future, the new Low Carbon & Chemicals Expo brings together companies driving innovation in hydrogen, ammonia, methanol, carbon capture, energy storage, chemicals, and clean energy. These sectors are essential to meeting rising global energy demand because they enable low-carbon solutions across power, transport, and industry.

Among the 100+ global companies confirmed to exhibit at the Expo are Topsoe, Excel International, Rittal, Vedanta Cairn and Veerum, jointly showcasing how cleaner fuels, advanced materials and circular solutions are unlocking the next wave of energy-driven prosperity.

ADIPEC 2025

Venue: ADNEC

Abu Dhabi

UAE

Dates:

3-6 November 2025

Website:

Kuwait makes new offshore gas discovery

Kuwait Oil Company (KOC) has announced a new discovery in the Al-Jazah offshore natural gas field

According to a KOC statement, the initial exploration well recorded the highest production rate from a vertical well in the Minagish formation in Kuwait’s history.

Initial tests at the Jazah-1 well indicate production exceeding 29 million cubic feet per day (mcf/d) of natural gas and more than 5,000 barrels a day of condensate, according to the statement.

With an area estimated at around 40 sq. km, the field is estimated to hold potential reserves of around one trillion cubic feet (tcf) of gas and more than 120 mn barrels of condensate, which may be revised upwards with further exploration in surrounding areas.

KOC said the reservoir has low CO2, no hydrogen sulfide and no associated water.

The new discovery follows other offshore discoveries including the Nokhatha field discovery last year, which is estimated at about 2.1bn barrels of oil and 5.1 trillion cubic feet of gas, and the Julaiah field early this year, described by KOC CEO Ahmad Jaber Al Eidan as a “strategic breakthrough.”

This is a result of KOC’s push to develop its offshore resources as it seeks to boost gas output and reduce its dependence on imported LNG. Phase 1 of its offshore exploration programme, consisting of the drilling of six wells, is underway, with planning for Phase Il also underway, with nine additional locations identified for further exploration and appraisal, according to Al Eidan.

Kuwait is the fifth-largest producer in OPEC, currently producing approximately 2.7mn bpd of oil, with plans to increase its production capacity to 4mn bpd by 2035. Al Eidan commented in an earlier interview with Oil Review Middle East, “Our strategy focuses on optimising production from mature assets, accelerating the development of high-potential reservoirs, and unlocking new growth frontiers, both onshore and offshore, to ensure sustainable and resilient capacity growth.”

He said the new offshore discoveries “significantly expand Kuwait's hydrocarbon frontier beyond the onshore legacy and add a new dimension to our long-term production sustainability,” adding that offshore development will play an increasingly vital role in KOC’s production mix in the coming decade.

The acquisition strengthens GPT Industries' role in helping operators mitigate corrosion and maintaining asset integrity. (Image source: Adobe Stock)

GPT Industries acquires Rectifier Technologies Inc.

GPT Industries, a global leader in sealing, electrical isolation, and remote asset integrity monitoring solutions, has acquired Integrated Rectifier Technologies Inc. (IRT), an Alberta-based manufacturer of transformer rectifiers and related products for the cathodic protection (CP) industry

This strategic acquisition brings together GPT’s expertise in flange isolation technology and remote asset monitoring with IRT’s long-standing reputation for reliable rectifier systems, further strengthening GPT’s role in helping operators mitigate corrosion and maintain asset integrity across energy and infrastructure sectors.

Founded in 2001, IRT has become a trusted supplier of transformer rectifiers and control systems, known for its C.P. Sentinel product line and commitment to certified, safety-focused designs. The company’s products are widely used in impressed current CP systems for pipelines, utilities, and water infrastructure throughout North America and across the globe.

Darin Lane, CEO of GPT Industries, said, “Together, we’ll enhance the technologies that support corrosion mitigation efforts, improve monitoring capabilities, and ultimately deliver greater value to our partners.”

Integrating IRT’s rectifier technology with GPT’s Iso-Smart remote monitoring platform will accelerate the development of advanced remote asset integrity systems, providing operators with deeper visibility into CP performance, streamlined data collection and faster response to field issues.

The acquisition aligns with GPT’s strategy of growth through partnership and technology advancement, reinforcing its commitment to supporting customers in safeguarding vital assets and extending the life of critical infrastructure.

Farabi Petrochemicals Company opens fourth Saudi LAB plant

Farabi Petrochemicals Company has inaugurated its fourth integrated Linear Alkyl Benzene (LAB) plant in Saudi Arabia

The US$950mn state-of-the-art facility, located in Yanbu Industrial City, adds 120,000 metric tons per year of LAB capacity. Built adjacent to Aramco’s refineries, the plant leverages locally produced kerosene and benzene feedstocks, ensuring world-class integration, efficiency, and sustainability performance.

The new plant underlines Farabi’s commitment to Saudi Arabia’s Vision 2030 objectives of downstream diversification, localisation and GDP growth.

The company also signed a new Memorandum of Understanding (MoU) with Unilever to expand their 20-year strategic partnership. Unilever is the world’s largest buyer of LAB, a key ingredient in household and industrial cleaning products.

The expanded agreement aligns Farabi’s capacity growth with Unilever’s constantly growing global demand in home care products, supporting innovation and sustainable growth. Both companies expressed confidence that this deepened collaboration will generate long-term value and advance their shared sustainability goals.

Eng. Mohammed Al Wadaey, CEO of Farabi Petrochemicals Group, said, “Farabi Petrochemicals is proud to be the world’s largest producer of LAB and NP which is the result of consistent growth, product diversification, advanced industrial infrastructure and dedication of our talented employees. We actively support Vision 2030 driving economic diversification, creating job opportunities, contributing to Saudi Arabia’s position as a global industrial hub, while maintaining a positive impact in the environment.”

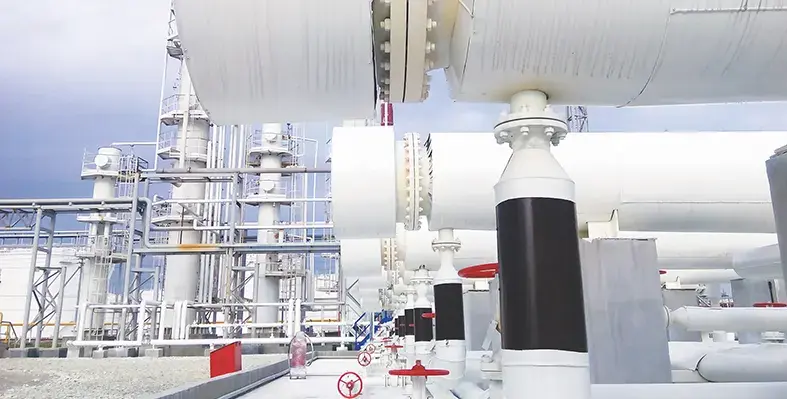

Multiple autonomous control AI agents were deployed at Aramco’s Fadhili Gas Plant. (Image source: Aramco)

Yokogawa deploys autonomous control AI agents at Aramco facility

Yokogawa Electric Corporation, a leader in process automation technology, has successfully deployed multiple autonomous control AI agents at Aramco’s Fadhili Gas Plant in the Kingdom of Saudi Arabia to enhance operational efficiency

The AI solution developed by Yokogawa uses multiple, coordinated AI agents of the Factorial Kernel Dynamic Policy Programming (FKDPP) reinforcement learning-based AI algorithm to directly and autonomously control and optimise acid gas removal (AGR) operations at the plant.

The solution was introduced in three phases, progressively optimising various sections until autonomous control of the core process in the AGR unit was achieved. To ensure safety, Yokogawa first created a simulator of the plant to train AI agents, and then evaluated their reliability and validity. Subsequently, they were integrated with Yokogawa's CENTUM VP integrated production control system to leverage the safety functions of the existing plant.

Initial results from Fadhili Gas Plant demonstrate a 10% to 15% reduction in its amine and steam usage, around 5% reduction in power usage, improved process stability, and a significant decrease in operator manual intervention, despite ambient condition changes.

Aramco Engineering Services senior vice president, Khalid Y. Al Qahtani, said, “Aramco has embarked on an ambitious plan to unlock value by deploying a wide range of industrial AI applications across our operations. The collaboration with Yokogawa is one of many initiatives that focus on improving efficiency, enhancing sustainability, and generating more value for our shareholders. It reflects how the company is harnessing advanced technology, including AI, to elevate its performance and reinforce its position as a technology leader in the energy sector. We look forward to building on this important milestone, as we explore further adoption of cutting-edge solutions that will contribute to a new era of industrial innovation.”

Kunimasa Shigeno, director, president & CEO, and representative executive officer of Yokogawa Electric, said, “We are honoured that Yokogawa was entrusted by Aramco to implement such ground-breaking technology in one of its major facilities. We are very pleased that the results have already exceeded expectations. Yokogawa is advocating the transition from industrial automation to industrial autonomy (IA2IA), and this deployment proves that we are ready to lead the way towards safe and secure autonomous operations for plants in the energy sector.”

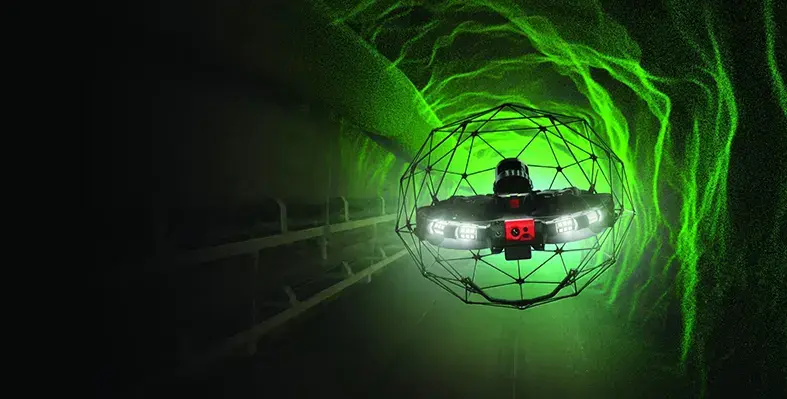

Webinar: Transforming oil and gas operations with the Elios 3 drone

Despite advances in digital technology, many oil and gas sites across the Middle East still rely on manual entry for tank and vessel inspections, resulting in days of downtime, high scaffolding costs and risk to human life

What if you could change all that with drone technology?

Inspections drones such as the Elios 3 are revolutionising the world of confined space inspections, improving safety, reducing downtime and enhancing operational efficiency.

Join us for an exclusive live webinar hosted by Flyability in association with Oil Review Middle East on ‘Transforming oil and gas operations with the Elios 3 drone’ on Tuesday 2 September at 2pm GST. Industrial experts will explain how drones such as the Elios 3 are transforming confined space inspections, and how you can integrate this technology into your operations seamlessly.

Key highlights:

Drone integration: learn how to safety and effectively implement drones in confined space

Safety and training: understand essential safety protocols and training strategies for your team

ROI: discover how to measure and achieve a strong return on investment with drone technology

Real world use cases: hear from the engineers using drone tech in the field on the impact Elios 3 is having on in oil and gas inspections.

Speakers and host:

Fabio Fata – senior sales manager, Flyability (moderator)

Eralp Koltuk – inspection lead engineer, Tüpraş

Danijel Jovanovic – director of operations, ZainTECH

Take your operations to the next level! Don’t miss out on gaining valuable insights into how drones can make inspections safer, faster and smarter .

From making inspections in hazardous confined spaces much safer to streamlining the whole process and providing valuable real-time data, you will get to see exactly how the Elios 3 is changing the game.

Decarbonising the lubricant oil industry

Fadi Al-Shihabi, sustainability solutions lead, KPMG Middle East, discusses how decarbonisation is transforming the lubricant oil industry and accelerating the Middle East’s journey to net zero

The lubricant (lube) oil sector is under growing pressure to minimise its environmental footprint as industries worldwide confront the realities of climate change. A rapidly growing industry in the UAE, it is currently estimated at 166.27mn litres, and is expected to reach a staggering 202.68mn litres by 2030. In the Middle East, where the current lubricant market is estimated at 2.94 billion litres and expected to reach 3.31bn litres by 2030, similar trends are evident in Saudi Arabia, Oman, and Qatar.

From the automotive industry to power generation, the lubricant oil sector is a widely growing area. It plays a critical role in keeping engines, machinery, and industrial systems operating efficiently, but its traditional production, packaging, and end-of-life management contribute significantly to greenhouse gas (GHG) emissions.

According to the International Energy Agency (IEA), oil and gas operations, including extraction, processing, and refining, account for approximately 5.1 Gt CO2e annually, or about 15% of global energy sector emissions. To remain on track for net-zero by 2050, these emissions must fall by over 60% by 2030.

The UAE has set itself enormous emissions targets – the UAE Net Zero by 2050 strategic initiative aims to achieve net-zero emissions by 2050 – with stakeholders in key sectors, including energy, implementing projects to decarbonise in line with their needs and growth requirements. Saudi Arabia’s Circular Carbon Economy framework and Oman’s Net Zero 2050 pledge echo similar decarbonisation ambitions.

The deployment and use of clean energy solutions is one of the UAE’s main pillars to address climate change and reduce GHG emissions. The country began financing clean energy projects more than 15 years ago and has invested over US$40bn in the sector to date. The Middle East region as a whole is set to receive over US$75bn in investments for renewable energy projects by 2030, according to a report released by the Energy Industries Council (EIC). Ahead of the COP28 summit in the UAE in 2023, more than 60 top executives from the oil and gas, cement, aluminium and other heavy industries agreed to cut their emissions to meet their climate obligations.

Within the lubricants sector, electrifying process heat, cutting methane leaks, and using low-emissions hydrogen, particularly in energy-intensive refining steps like hydrotreating and hydroisomerisation, are vital for efficiency improvements. These innovations are critical as it is estimated that a single liter of lubricant can generate over 3.5 kg CO₂e. Refineries across the GCC are piloting hydrogen and CCUS technologies to curb emissions in lubricant production.

Innovation powering the lubricants industry

The journey of lube oil begins with crude oil extraction, followed by vacuum distillation to separate heavier fractions suitable for base oil production. These base oils undergo further refining processes such as hydrotreating, hydroisomerisation, dewaxing and other processes, enhancing their viscosity, stability, and longevity.

Recent innovations in catalyst technology and feedstock selection are driving both product quality improvements and emissions reduction. Producers are also blending biomass-derived feedstocks with conventional inputs to create lower-carbon base oils. These bio-based oils perform similarly to fossil-based ones but have less carbon footprint and can be processed using existing infrastructure. Scientists are also exploring entirely renewable base oils.

However, innovation doesn’t stop at production. Digital monitoring tools help reduce lubricant waste during use. For example, Finnish company Lassila & Tikanoja installed real-time oil monitoring across its hydraulic systems and reduced oil use by 13,400 litres over four years, saving around 10 tonnes of CO₂e annually. They also cut lubricant-related emissions by up to 80% through smarter maintenance without affecting performance.

Packaging and handling

When it comes to packaging, manufacturers are increasingly optimising designs by reducing material use and enhancing handling and distribution. While traditional rigid plastics and metals have historically provided the necessary protection, they also present significant challenges in terms of disposal and GHG emissions.

Consequently, the lubricant industry is undergoing a transition toward low-carbon packaging alternatives that can maintain safety and performance while addressing environmental concerns. Lightweighting and design optimisation reduce raw material demand, shipping weight, and CO2 emissions per litre delivered, without compromising safety or performance.

TotalEnergies has been at the forefront with the integration of 50% post-consumer recycled (PCR) HDPE in its premium lube oil bottles, launched in France and Belgium since September 2023. These bottles retain the same weight, design, and performance while significantly reducing the carbon footprint.

Lowering cradle-to-grave emissions

Beyond production and packaging, extending lubricant life is key to decarbonisation. Modern additives have enabled lubricant change intervals to increase from 5,000 km in legacy vehicles to upwards of 30,000 km in modern engines.

Bio-based or biomass-balanced additives further support environmental goals by reducing the emissions linked to additive manufacture and enhancing overall oil performance. The result is less frequent oil manufacture, transport, and disposal.

As the UAE accelerates its journey towards decarbonisation, these steps will be crucial in ensuring the responsible end-of-life management of lube oils. Technological advancements and environmentally friendly formulations will create new growth avenues and set a new benchmark in the UAE’s industrial revolution. As neighbouring countries pursue similar ambitions, regional collaboration in innovation and policy will be key to transforming the Middle East lubricant landscape.