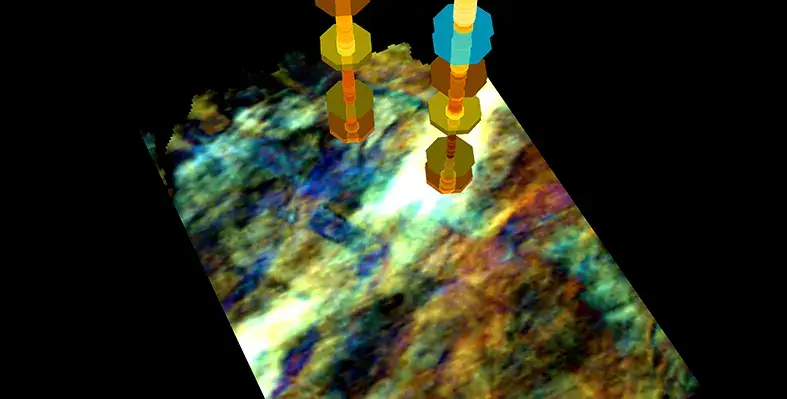

DUG Insight combines interpretation, visualisation, processing, imaging and quantitative analysis – at any resolution. (Image source: DUG)

With operators across the Middle East acquiring tens of thousands of square kilometres of high-fold 3D and OBN seismic data, today’s interpretation challenge spans hundreds of billions of traces – demanding next-generation software built for true scale

Modern exploration teams need more than incremental upgrades; they need to connect every stage of the seismic workflow and make collaboration seamless.

For many companies, that challenge is compounded by fragmented workflows – with processing, imaging, and interpretation handled on separate packages. DUG Insight eliminates that complexity, uniting every stage of the seismic workflow within one powerful, interactive software designed for scale, speed, and collaboration.

Built first for DUG’s own geoscientists and now used in over 35 countries, DUG Insight combines interpretation, visualisation, processing, imaging and quantitative analysis – at any resolution. Designed for seismic/single/multi-channel and sub-bottom profiler data, the software offers a complete suite of industry-leading tools, with integrated 3D visualisation and mapping for pre-stack, 2D/3D and time-lapse studies. Quantitative interpretation (QI) functionality includes statistical rock physics and simultaneous absolute inversion. Featuring an intuitive, interactive interface, DUG Insight automates labour-intensive tasks and enables a seamless, productive user experience, while encapsulating project configuration and operation within a consistent workspace. Crucially for operators evaluating platform strategy, DUG Insight is not “interpretation-only” or “processing-only” – it is both, by design.

The software supports both on-premises and cloud-based deployments through DUG’s high performance computing system, with flexible licensing and round-the-clock technical support. Recent developments include AI-assisted interpretation tasks such as log interpretation and fault picking, further enhancing efficiency.

DUG’s continual investment in research and development keeps DUG Insight at the leading edge. The company’s revolutionary elastic multi-parameter FWI imaging technology, included in DUG Insight, is a complete replacement for the traditional seismic processing, imaging and elastic rock property inversion workflows.

With its new office in Abu Dhabi, DUG is working even closer with regional partners to support large-scale land and offshore projects across the Middle East. Whether for mega-merges, massive OBN datasets, or ultra-dense onshore surveys, DUG Insight is a single unified software to process, image, interpret and analyse seismic data – efficiently, interactively and at any scale.