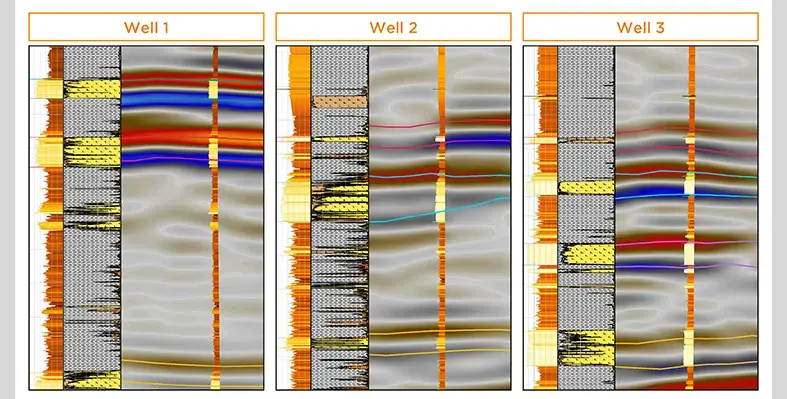

A multi-well correlation for three wells. Shown (from left to right for each well) are gamma ray, AI-predicted lithology, and far-stack seismic amplitude with the gamma ray curve in the well position. (Image source: DUG)

A multi-well correlation for three wells. Shown (from left to right for each well) are gamma ray, AI-predicted lithology, and far-stack seismic amplitude with the gamma ray curve in the well position.

Faster. Consistent. Scalable. How AI is transforming lithofacies interpretation

Lithofacies interpretation remains one of the most fundamental tasks in subsurface evaluation – and one of the most time-intensive. Despite advances in logging technology and computing power, workflows are still dominated by manual interpretation, subjective judgement and inevitable variability between interpreters. When dozens or hundreds of wells must be assessed, particularly in early-stage screening or regional studies, this inconsistency can delay decisions around reservoir presence, interval ranking and further petrophysical review.

A new deep-learning workflow developed at DUG demonstrates how that bottleneck can be significantly reduced – delivering fast, reproducible lithofacies predictions directly from standard wireline logs. Rather than replacing geological interpretation, the approach provides a consistent first-pass screening tool that allows interpreters to focus attention where it adds the most value.

A key differentiator of the workflow is its foundation in rock physics. Any supervised machine-learning model is only as reliable as its training labels, and in this case those labels are derived from carefully curated end-member lithologies. These end members represent the cleanest and most internally consistent examples of sandstones, shales, siltstones and carbonates, selected only where wireline responses align physically and geologically. By excluding intervals affected by poor borehole conditions or noisy measurements, the resulting training dataset remains objective, consistent and firmly grounded in established rock physics relationships.

The model architecture combines a transformer-based sequence model with a one-dimensional convolutional neural network, also previously developed by DUG. This enables it to capture both long-range stratigraphic trends and local log-response variability, while handling missing data through attention masking. Crucially, the workflow accepts whichever subset of common wireline curves is available for a given well, allowing lithofacies prediction even in older or incomplete datasets.

Case studies using legacy data illustrate how DUG’s workflow delivers insight beyond speed alone. Artificial intelligence (AI)-generated lithofacies predictions highlighted subtle inconsistencies caused by density spiking and sonic cycle skipping – issues that were not immediately apparent in conventional single-well analysis. By flagging these intervals, the workflow guided targeted quality control and conditional correction, improving multi-well correlation without introducing artificial geological trends.

Rather than obscuring interpretation, DUG’s workflow makes inconsistencies visible – highlighting where log behaviour departs from rock physics expectations and directing interpreter attention where it is most needed.

This work will be presented by DUG’s machine learning software engineer, Kyle Rosa, at the SEG | DGS | SPE KSA Workshop: Bridging the Gap: Geosciences to Engineering in Al Khobar, Saudi Arabia, from 10–12 February 2026.

As geoscience datasets continue to grow in size and complexity, AI-augmented interpretation workflows help enable faster, more consistent subsurface decisions – without removing the interpreter from the decision-making loop.