Sean Donegan, CEO, Satelytics. (Image source: Satelytics)

Sean Donegan, CEO, Satelytics discusses the potential of AI-powered geospatial analytics to detect pipeline leaks

The importance of the Middle East to the global energy market is well-understood but worth emphasising. Between 2024 and 2025, roughly a third of the world's oil flowed from the region. With domestic and international demand continuing to soar, it is clear that both the past and the future of global oil and gas run directly through the Middle East.

At the same time, the Middle East, in ramping up its oil production, is increasingly running up against a problem endemic to all oil-producing regions: the fallibility of ageing or otherwise defective pipeline infrastructure, and the subsequent damage caused by leaks. These leaks cause significant environmental damage, divert limited resources to remediation efforts, and put oil and gas personnel, as well as (in some cases) surrounding residents, at risk.

Any increase in oil production would entail a concomitant increase in dangerous leaks. But as recent technological advancements have demonstrated, this doesn't have to be the case. In recent years, AI-powered geospatial analytics has emerged as a highly effective method of leak detection – one that is already sparing oil and gas producers from catastrophe in the Middle East and around the globe.

What is geospatial analytics? How does AI fit in?

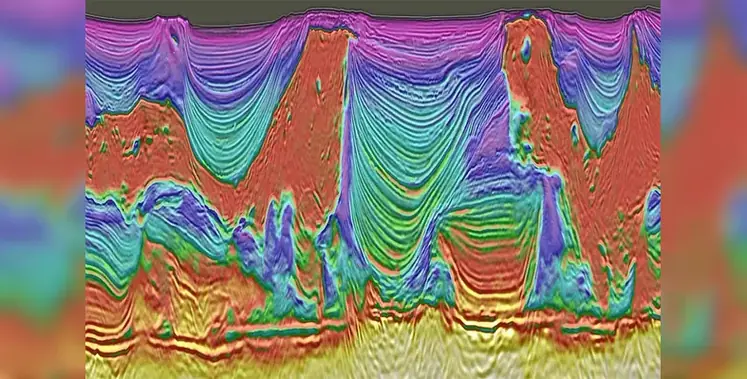

Geospatial analytics is the analysis of satellite imagery, and is fundamentally, a high-tech method of identifying problem points across unusually vast swathes of terrain. It begins with multispectral and hyperspectral imagery, which is gathered from a variety of sources, including unmanned aerial vehicles, planes, and fixed cameras. This imagery is then analysed by advanced artificial intelligence, which pinpoints precisely where leaks are occurring, near-instantly alerting businesses to potential issues.

The sheer scale of most oil and gas assets, more sprawling by far than those found in any other industry, helps explain why this technology is so useful. Take the example of Aramco, which is responsible for 3,140 miles of crude oil pipelines, according to the Organization of Arab Petroleum Exporting Countries. In any region, this degree of sprawl would be impossible to oversee by manual means. But the nature of the terrain involved makes the problem even more vexing. Aramco's Petroline, for instance, runs through the Empty Quarter, or the Rub' al-Khali, which is the largest continuous sand desert in the world. This challenging terrain has no permanent settlements, which means that when leaks do occur, days or weeks can pass before they're properly noticed.

The use of geospatial analytics, by contrast, ensures that these leaks are flagged in close to real-time, with an abundance of information for businesses to act on – including the specific problem, the location, and the magnitude of the disruption. This allows oil and gas producers to delegate relevant remediation personnel to take care of the issue before it spirals out of control.

Today, the technology is able to assist oil and gas producers in the US and Europe through the use of AI-powered geospatial analytics, and the technology is also being deployed to the Middle East as part of a broader global rollout.

US initiatives

North Dakota has a long history of pipeline leaks, which in 2017 compelled Governor Doug Burgum to take substantial measures to address the problem. The Intelligent Pipeline Integrity Program (iPIPE), as it was called, was launched with the aim of creating a fruitful partnership between government and industry on the pipeline problem. Through geospatial analytics, leak reports were delivered to consortium makers within hours of capture, showing results including the location and magnitude of liquid leaks.

The result was a significant reduction in pipeline leaks in the area. This reduction so impressed one of iPIPE's founding members that Satelytics was contracted to monitor their entire fleet of assets in the region, spread across nearly 10,000 sq.km. This effort, too, identified countless leaks in their infancy and spared the oil company from a number of potential disasters.

These successes piqued the interest of producers in Texas and led directly to a new initiative in the region: an unprecedented, industry-led collaboration designed to monitor infrastructure throughout the Permian Basin for liquid leaks, methane leaks, encroachment, and similar risks.

Geospatial analytics in the Middle East

From these origins, Satelytics has since scaled globally. Beyond our operations in Europe, we are now monitoring pipelines for a wide range of Middle Eastern companies, including operators in the UAE, Iraq and Qatar. These efforts have already helped to detect numerous leaks, in addition to flagging potential land encroachments and even testing water quality.

Conclusion

The environmental benefits of AI-powered geospatial analytics in an oil and gas context are indisputable: major players across the industry agree that it has a significant role to play in reducing emissions and forestalling negative climate events down the line. But its present-day benefits are just as striking, which explains why oil and gas companies across the world – from the Permian Basin to the Rub' al-Khali – have rushed to integrate the technology.

Satelytics uses cloud-based, geospatial analytics to analyse multispectral and hyperspectral imagery to identify pipeline leaks and other environmental issues.