Wael Radwan, director, software and control and intelligent devices for Middle East, Türkiye and Africa at Rockwell Automation, highlights the shift to targeted digitalisation that delivers measurable ROI and enables future-ready autonomous operations

In a sector accustomed to long project timelines and substantial capital outlay, Middle East oil and gas operators are now applying even more strict investment discipline. Digital initiatives must demonstrate their value through clearly defined returns, not merely conceptual promise. Every project must now serve a multi-dimensional purpose, supporting profitability, reducing emissions, strengthening compliance and enhancing resilience. A digital solution that cannot fulfil those aims does not survive the business case. In contrast to earlier waves of digital adoption which were about exploring potential, what matters now is performance, efficiency and bottom-line value. Pilots and proof-of-concept studies have become essential tools for determining the viability of new technologies. If the data does not back the decision, the deployment does not proceed.

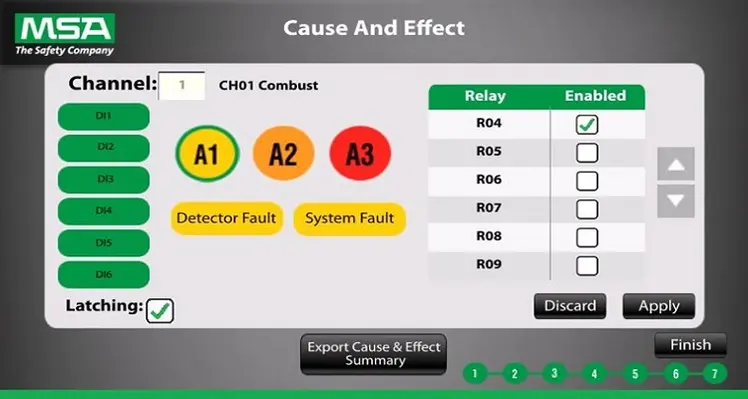

One recent successful pilot, undertaken by a national operator in the Gulf, trialled model predictive control (MPC) in a brownfield upstream facility to improve energy utilisation, opening the door to broader autonomy discussions across the asset portfolio. These pilots are now becoming the currency of confidence, demonstrating value in operational terms before scaling further.

From automation to autonomy

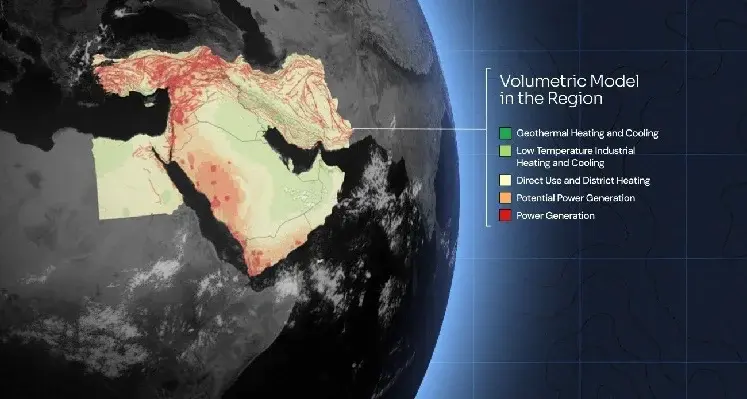

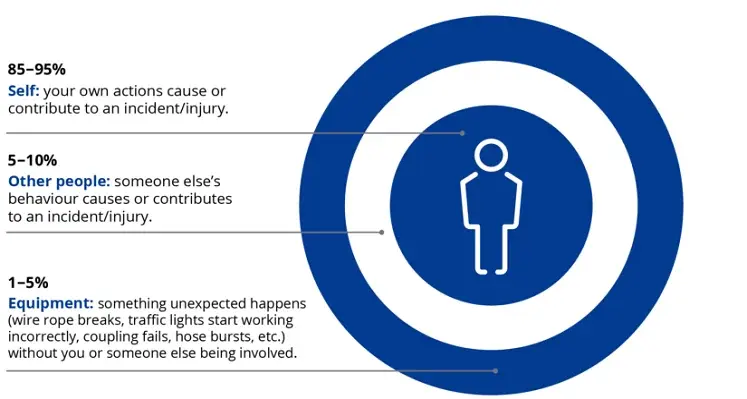

Automation has long been embedded across the Gulf's oil and gas infrastructure, but the future lies further along the spectrum, with autonomy, which represents a strategic response to some of the region's most pressing operational challenges. Remote assets, hazardous environments and constrained technical labour pools all favour solutions that reduce reliance on human presence.

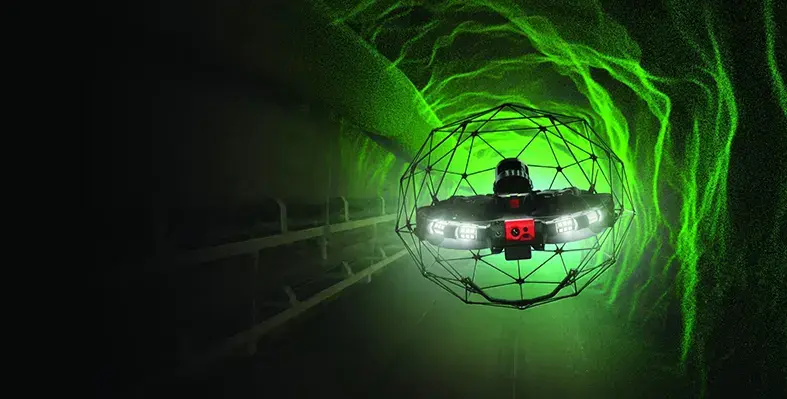

Unmanned operations are no longer an aspiration; they are entering deployment. In one offshore pilot, an autonomous robot has been deployed to monitor pipeline integrity, replacing routine manual inspection. The robot patrols assigned zones, records video and sensor data, and integrates this information into the control system, eliminating the need for helicopter-supported human intervention. The cost and safety implications are profound.

In another case, robotics is being tested in high-temperature process units where human access is restricted. Temperatures exceeding 500°C and strong electromagnetic fields make maintenance work dangerous and infrequent. By using robotic platforms coupled with intelligent control software, inspections are being conducted without shutdown, significantly improving equipment uptime and reducing operational risk.

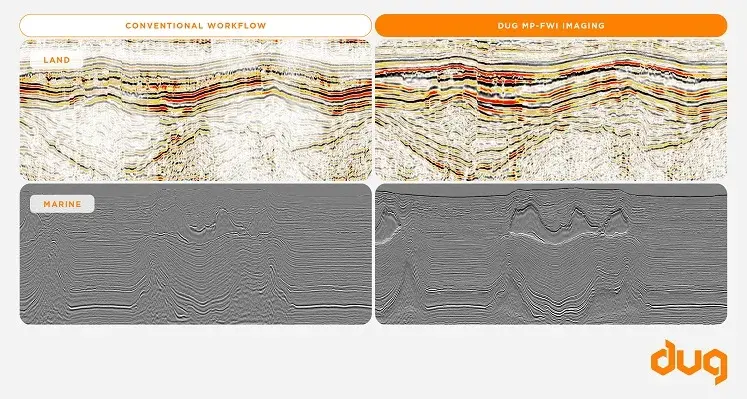

This step change from automation to autonomy is underpinned by increasingly sophisticated digital architectures. It is no longer just a matter of automating manual steps. It requires systems capable of interpreting alarms, predicting failure modes, and executing closed-loop responses without human command. These are currently being piloted, with the Middle East's largest operators leading the charge.

Data without context is not intelligence

The foundations of autonomy, and indeed all ROI-based digitalisation, depend on the ability to contextualise data. Oil and gas assets generate enormous volumes of sensor, process and transactional data. But raw data is not intelligence. It must be connected, contextualised and made accessible across operations. Contextualised data is the enabler of predictive asset strategies, advanced planning models and autonomous control.

Many Gulf operators still contend with fragmented data environments. OT and IT systems remain siloed. Cloud strategies are currently under development but not yet universally adopted. This fragmentation impedes predictive maintenance, slows root-cause analysis and creates decision-making bottlenecks.

To address this, operators are investing in unified data platforms that consolidate operational and enterprise data into a single, structured layer. A major pilot project underway in the UAE involves aggregating data from multiple upstream installations into one real-time environment. The aim is to transition from a system of fragmented visibility to one of integrated insight, where data from production, maintenance, energy management and logistics can be analysed collectively to drive better outcomes.

Trust is also evolving. Historically, there was deep scepticism toward cloud-hosted industrial data. Concerns around ownership, security and transparency were barriers to adoption. That resistance is diminishing. Operators are becoming increasingly comfortable with the idea that cloud platforms can offer not only flexibility and scalability but also security and control, provided that governance frameworks are in place.

Consultancy over technology

The shift from trend-based to outcome-based digitalisation has also reshaped how technology is delivered. There is growing recognition that digital tools are only as effective as the strategies behind them. This has driven increased uptake of digital consultancy services, where solutions are co-designed with operators around their specific goals, asset constraints and regulatory context.

For oil and gas producers in the Middle East, this consultancy-led approach is proving essential. The region's operators face unique challenges, including environmental, geopolitical, and infrastructural ones, and there is no single blueprint for transformation. Effective digitalisation must be locally informed and globally benchmarked.

Recent engagements have focused on redesigning operations around ROI-centric principles. Rather than starting with a technology suite, consultants begin with operational KPIs, production targets, energy efficiency thresholds, and maintenance budgets and work backwards to identify the digital tools that best support those goals. This approach avoids over-investment, accelerates value and reduces resistance among internal stakeholders.

Energy management is a key area where consultancy is delivering results. By applying machine learning and data modelling to existing instrumentation data, operators are identifying inefficiencies previously hidden in the noise. The result is not just reduced energy expenditure but also improved emissions performance and enhanced reporting capabilities for regulators and investors alike.

As these digital strategies mature, modular platforms are allowing operators to scale their transformation gradually, starting with monitoring, progressing to analytics and ultimately embedding AI in control decision-making. This staged approach supports faster ROI realisation while building the digital confidence needed for more ambitious moves toward autonomy.

ROI is the new currency of transformation

Flashy dashboards, pilot projects with unclear value, or technology for its own sake no longer pass muster. Every deployment must deliver clear, measurable outcomes. ROI is not a hopeful result, it is the starting condition.

The operators that will thrive in this next phase are those that treat digital not as a silver bullet but as a structured discipline. They will define business objectives first, validate solutions through field-tested pilots, and scale only what works. They will integrate data at every level, automate where it makes sense, and explore autonomy where it drives true business advantage. They understand that smarter production and faster payback are not just aspirations; they are realities and requirements. And they are achievable if you start with value and build from there.