The Norwegian oil and gas operator DNO ASA has been assigned the 20 per cent interest in Kurdistan’s Tawke oil field as payments of receivables owed to the company for past crude oil deliveries

Exploration & Production

Africa Re faces losses in South Africa and Middle East in H1 2017

African Reinsurance Corporation (Africa Re) has announced that the losses in South Africa and in the Middle East pushed down the company’s net profit to US$7.6mn in the first half of 2017 from US$32.6mn in the same period in 2016

Packers Plus and BP Oman achieve operational efficiencies in HPHT wells

Packers Plus Energy Services Inc. has announced recent developments with BP Oman Exploration (Epsilon) Ltd. Collaborations include development of a customised completion system, successful installation and subsequent stimulation of two high pressure/high temperature (HPHT) wells in Omans Khazzan field

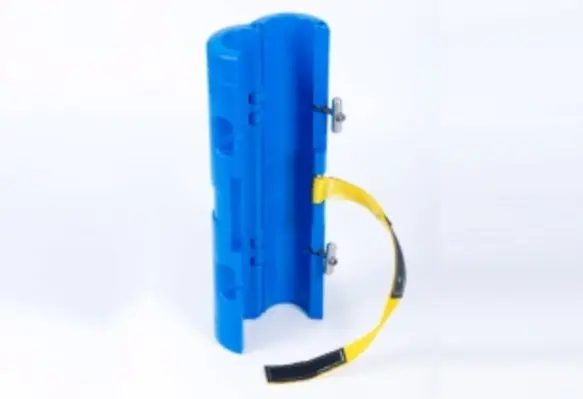

Emerson launches drilling jar clamp for increased safety and well integrity

Emerson Automation Solutions has launched the latest product within its polymer completions solutions range – the PolyOil® JAR Handling Clamp – for increased safety and well integrity

One key threat to well integrity and safety in drilling and completions operations today is the danger of jars firing prematurely at the surface prior to being deployed into the well. Jars are mechanical devices used downhole to deliver an impact load to another downhole component (especially when that component is stuck) and include a firing mechanism that activates when the necessary compression or tension has been applied to the running string. The inadvertent firing of such jams prematurely, however, can pose a hazard and lead to possible injuries and the dropping of the bottom hole assembly if pins are sheared.

Said Matthew Armstrong, director downhole operations for Emerson’s PolyOil/Roxar business: ”Our PolyOil solutions are all about bringing predictability, safety and innovation to downhole drilling and completions. This is what we have achieved with the PolyOil JAR Handling Clamp, improving the effective operation of jars, the well’s integrity and – most importantly of all – personnel safety.”

The new PolyOil JAR Handling Clamp acts a safety device to prevent the jar from cocking and firing, with the jar unable to fire unless the fishing neck – designed to enable running and retrieval tools to reliably engage and release – is closed. Therefore, when the clamp is fitted to the jar, the rod is kept in the open position, thereby preventing premature firing during the handling of the jar at the surface. The clamp also prevents the jar rod from being damaged during transportation and keeps it debris-free during storage. Applications for the new JAR Handling Clamp include drilling, drill stem testing (DST) jars, coil tubing and wireline applications.

The PolyOil JAR Handling Clamp and many other PolyOil products use a range of high impact wear resistant materials with the natural properties of the polymers making them low weight, safe, easier to handle than metal, andmore resilient. Other key features of the clamp include a hinged design with the clamp simple and fast-to-fit and a toggle/swing bolt for fast latching operations.

Visuray introduces the VR90s advanced diagnostic tool for well inspection

Following the successful launch of the VR90 downhole X-ray diagnostic tool in 2015, Visuray has developed an improved version of the tool known as the VR90s advanced diagnostic tool