Pelco's heavy-duty ruggedised security cameras are designed to meet the evolving demands of modern oil and gas operations. (Image source: Pelco)

Polina Mamont, technical evangelist for Pelco, provides a comprehensive overview of Pelco’s evolution under the stewardship of Motorola Solutions and how oil and gas operators in the Middle East can benefit from the brand’s new strategic direction

For over 65 years, Pelco has built a legacy of reliability and service, especially in environments where the deployment of trusted devices is essential. But the demands on oil and gas infrastructure have changed. Harsh environments, increasing cyber risk and stricter compliance pressures are reshaping how companies approach safety and security.

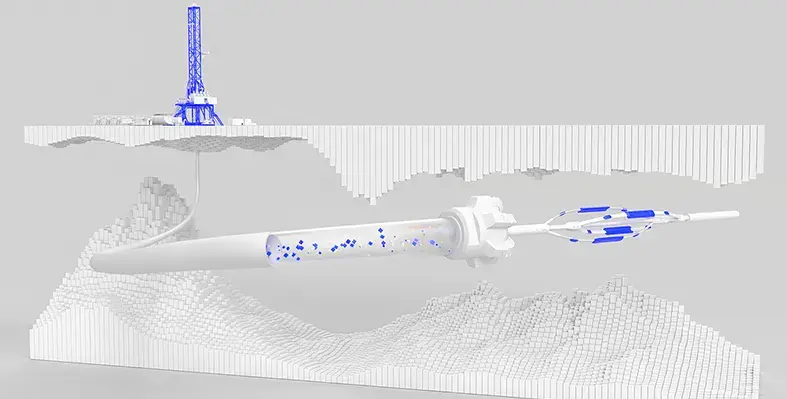

The old playbook of hitting ‘record’ and hoping for the best is no longer enough to keep pace with the evolving security challenges. Security teams need security technology that supports faster decision-making, remote diagnostics and real-time insights across sprawling, often hazardous facilities. That’s why Pelco has made a focused shift, building out our portfolio with heavy-duty ruggedised security cameras, designed to meet the evolving demands of modern oil and gas operations.

A legacy of innovation reinvented

Pelco’s renewed strategic direction centres on delivering high-performance cameras and intelligent edge devices that integrate easily with your existing ONVIF-conformant VMS, without requiring a complete system replacement. Since joining Motorola Solutions in 2020, Pelco has redesigned and re-engineered most of its camera lineup, introducing new capabilities through targeted acquisitions:

● Videotec – ruggedised cameras and housings built for hazardous and corrosive conditions

● IPVideo – smart sensors delivering visibility to privacy-sensitive areas

● Silent Sentinel – long-range visible and thermal imaging for perimeter and infrastructure protection

● Calipsa – cloud-based analytics to support AI-driven detection and false alarm filtering

This expanded portfolio reflects a broader shift toward intelligent, flexible security. By combining durable hardware with edge analytics and cloud integrations, Pelco devices can help improve visibility across critical zones, identify abnormal behaviours and support compliance with safety regulations.

The missing ingredient for a safer and more secure facility

The Middle East plays a critical role in the global energy supply, producing approximately 30% of the world's oil and around 17% of the world's natural gas. But the region’s environmental and geopolitical realities present unique security challenges. From extreme heat and corrosive sea air to long-range perimeter requirements and cyber-physical threats, operators are under pressure to secure infrastructure without interrupting operations.

The expanded Pelco portfolio range meets these challenges head-on.

Engineered for hazardous and corrosive environments

From desert facilities to offshore platforms, Middle East oil and gas sites require video security built to withstand extreme heat, corrosion and hazardous conditions. Pelco’s specialty camera lineup offers a wide range of configurations, including PTZ, thermal, bispectral PTZ, fixed, compact and IR PTZ, engineered for the region’s most demanding environments.

With models constructed from heavy-duty 316L stainless steel, these cameras are designed to resist the corrosive effects of coastal sea spray and operate reliably in the region's extreme temperatures. They comply with key international standards, such as ATEX and IECEx, ensuring they meet the stringent requirements of your sites. With high-resolution imaging, environmental hardening and advanced detection capabilities, they provide the situational awareness needed to help protect people, assets and operations in any conditions.

Long-range Silent Sentinel cameras help protect boundaries across large distances

For the unique challenge of securing offshore platforms, pipeline corridors and coastal terminals, Silent Sentinel camera systems provide critical long-range situational awareness. These ruggedised camera systems are engineered to detect and classify threats like vehicles, vessels and drones from kilometres away, providing your team with advanced warning to act proactively.

With modular camera systems like Jaegar and Aeron, available in a wide variety of thermal, optical and multispectral lens combinations, operators can observe wide areas day and night, even in fog or complete darkness. These systems integrate seamlessly with radar, range finders and other sensors to support long-range threat detection.

Smart Analytics provides proactive intelligence to protect people and assets

The true power of a modern video system lies in its ability to understand what it sees. Our cameras are equipped with Pelco Smart Analytics, transforming them from passive recorders into proactive detection devices. These AI-driven analytics can classify people and vehicles, and identify behaviours such as loitering near restricted areas, unauthorised entry or absence from zones that require constant human oversight, like control stations on offshore platforms or pump rooms in refineries.

This intelligence extends beyond security to help protect your operations and workforce. Thermal models with radiometric analytics can identify abnormal temperature spikes in critical equipment, like gas compressors or switchgear panels, sending an alert that allows for proactive maintenance before a failure leads to costly downtime. For an additional layer of intelligence, Elevate-enabled cameras streamline maintenance and unlock advanced analytics, such as PPE detection, helping workers stay compliant with safety gear requirements in hazardous zones.

Halo Smart Sensors for protection in privacy zones

In oil and gas environments, areas like restrooms, locker rooms and enclosed break areas still present potential safety and compliance risks. Halo Smart Sensor is an all-in-one device that ensures privacy by operating without any visual or audio recording, instead utilising a suite of advanced sensors to detect a wide range of risks in real-time.

Its air quality sensors can identify dangerous changes that might signal a chemical leak, such as rising VOC levels, or detect prohibited smoking and vaping in hazardous zones. The Halo sensor’s audio analytics can recognise acoustic signatures, such as aggression or a call for help, providing an immediate alert to potential security incidents. In an emergency, Halo’s built-in, colour-coded lights can provide way-finding illumination to help guide your workers to safety and comprehensive protection across every part of your facility.

Upgrade your security without disrupting operations

A complete overhaul of a security system in an active oil and gas facility is a monumental task. The risk of production delays and the logistical complexity of working in hazardous zones often make a full "rip-and-replace" project unrealistic, especially when many facilities rely on legacy operational technology.

This is why Pelco is committed to open platform technology. Our cameras are designed to integrate seamlessly with all leading ONVIF-conformant VMS platforms, including Genetec, Milestone and Avigilon Unity, allowing you to enhance your security capabilities without discarding your current infrastructure.

This approach provides a practical path to modernisation. You can begin upgrading your security posture today by adding intelligent Pelco cameras into your existing infrastructure, allowing you to introduce advanced analytics and enhance operational visibility without the massive cost and disruption of starting from scratch.

Coming soon: Live webinar

We’re hosting an exclusive online event for oil and gas leaders on 16 September at 3:00 pm GST. In the session, we’ll discuss three of the main challenges faced by oil and gas operators: safety, security and productivity, and how advanced video security technology can help to address them.

Interested?

Register for the webinar here.

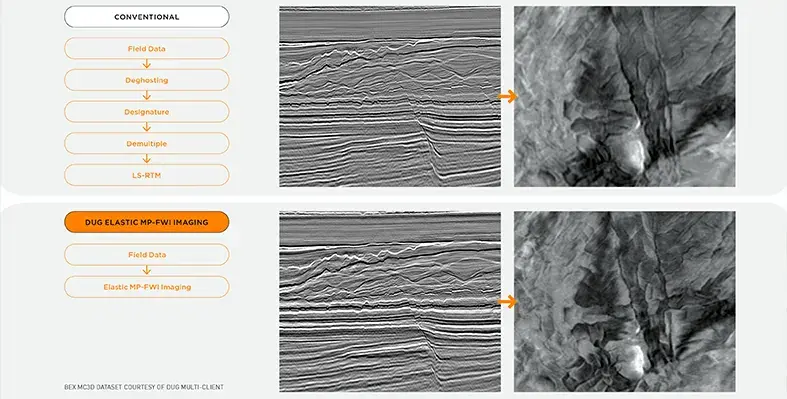

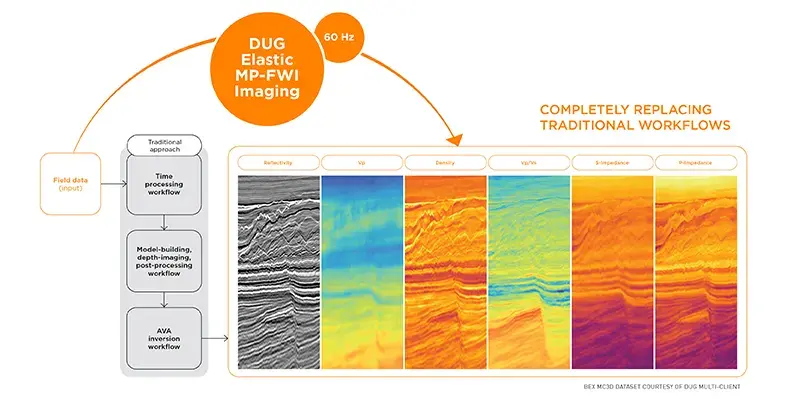

Multiples are normally considered as problematic noise, however they illuminate the subsurface in complementary ways to primary reflections. When imaging with primaries and multiples the subsurface is sampled far more completely, and with a wider range of angles — constraining the inverted reflectivity, rock properties and attenuation.

Multiples are normally considered as problematic noise, however they illuminate the subsurface in complementary ways to primary reflections. When imaging with primaries and multiples the subsurface is sampled far more completely, and with a wider range of angles — constraining the inverted reflectivity, rock properties and attenuation.