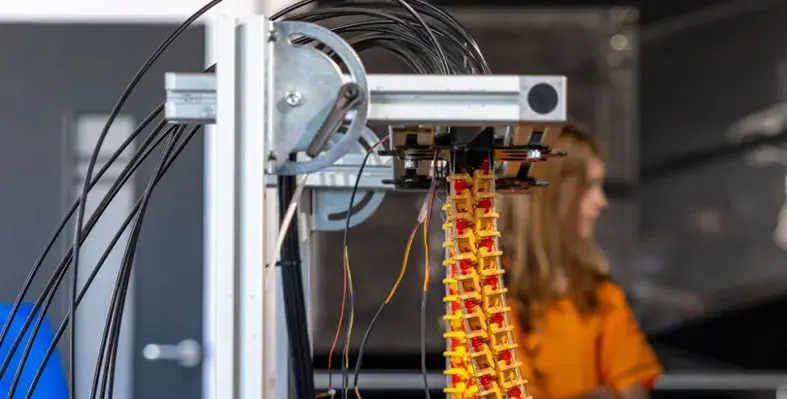

The new underwater robot adapts to offshore structures on contact. (Image source: National Robotarium)

A new underwater robot that adapts to offshore structures on contact has been developed through a collaboration between the UK’s National Robotarium and Senai Cimatec in Brazil

Designed and developed by engineers at the National Robotarium, the UK’s centre for robotics and AI at Heriot-Watt University, the tentacle-like underwater robot features a soft, bendy design that conforms to structures during contact, offering significant advantages over conventional rigid manipulators when working near delicate or complex subsea equipment. It works by combining a flexible backbone with a system of tendon-like cables that control its movement. Special sensors help it understand its position and shape underwater, allowing the robot to make precise movements even in turbulent conditions, making it ideal for deploying from underwater vehicles to inspect offshore energy and marine infrastructure.

Tests conducted at the National Robotarium show the robot can accurately position its arm and maintain stability when subjected to external forces of up to 300g, even correcting its position within seconds if disturbed.

The breakthrough is set to revolutionise offshore inspection, as it could enable smaller underwater vehicles to perform sophisticated inspection tasks rather than the large vessels and divers traditionally used, thereby reducing operational costs while improving personnel safety and environmental sustainability.

Rowanne Miller, project manager at the National Robotarium, said, “Our team has taken this innovative underwater robot from initial concept through design and development to successful testing in real-world conditions. What makes this particularly exciting is that we’ve created a solution that doesn’t just incrementally improve existing technology – it fundamentally changes how we can approach underwater inspection tasks, opening up new possibilities for safer, more precise interaction with critical subsea infrastructure and potentially transforming how we maintain and protect our offshore assets for decades to come.”

Lucas Silva, lead researcher at SENAI CIMATEC, added, “We worked together with the National Robotarium to conceive an innovative take on underwater manipulation, opening up new use cases for the industry. This new branch of development represents an important and disruptive upgrade to our robotics development roadmap, and the seamless cooperation with The National Robotarium played a key role in this new achievement, setting new standards for future international partnerships”.

The soft robotic tentacle will be on display at the inaugural UK Robotics Expo, taking place at The National Robotarium on 18 September.

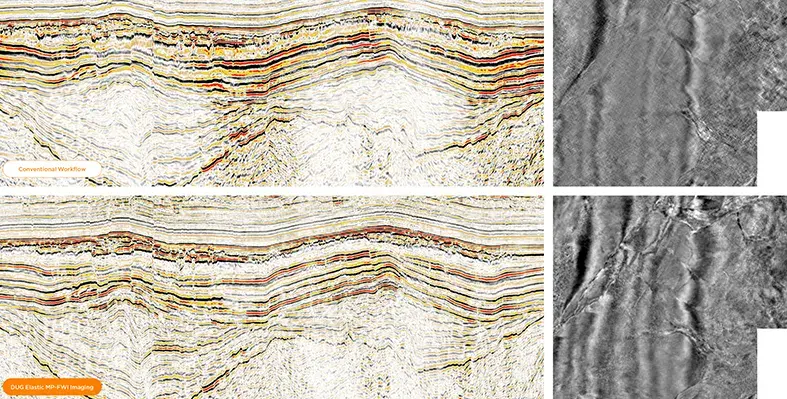

Significantly better illumination and event continuity is obvious when comparing the sections in the figure, thanks to DUG Elastic MP-FWI Imaging of the full wavefield — that includes interbed multiples. Incredible near-surface detail has been resolved, as can be seen on the shallow depth-slices to the right. Subtle structural and stratigraphic features that were simply not imaged with a conventional processing and imaging workflow have now been resolved.

Significantly better illumination and event continuity is obvious when comparing the sections in the figure, thanks to DUG Elastic MP-FWI Imaging of the full wavefield — that includes interbed multiples. Incredible near-surface detail has been resolved, as can be seen on the shallow depth-slices to the right. Subtle structural and stratigraphic features that were simply not imaged with a conventional processing and imaging workflow have now been resolved.