SLB and Eni, through its subsidiary Enivibes, have announced an alliance to deploy e-vpms® (Eni Vibroacoustic Pipeline Monitoring System) technology, an innovative vibroacoustic wave detection system capable of providing real-time analysis, monitoring and leak detection for pipelines around the world

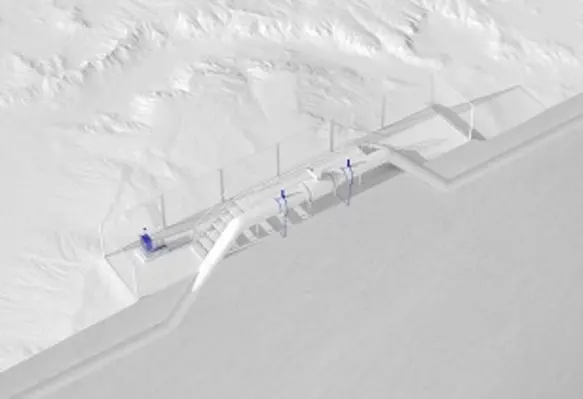

Developed by Eni and Enivibes for continuous monitoring of oil and gas pipelines in real time, e-vpms technology is ideal in situations where fibre-optic infrastructure is limited. Multiple sensors are deployed at discrete distances along the pipeline to monitor both the fluid behaviour within the pipe and acoustic waves travelling along the pipe wall. Sensors can be placed up to 50 km apart and have low bandwidth and power requirements. The technology can be retrofitted to any pipeline, regardless of age, providing immediate integrity data essential for maintaining a network’s continually reliable operation.

Enivibes will bring the new proprietary pipeline integrity technology to the global market through SLB’s industry-leading digital expertise and operations in more than 100 countries. The alliance covers the deployment of e-vpms technology for pipelines transporting liquid hydrocarbons and produced water and enables the detection of product loss attributable to external events such as attempted product theft or accidental impact, corrosion related leak events, and land movement events caused by earthquakes or landslides.

“The e-vpms technology will equip operators with the ability to extract real-time data from even their oldest assets,” said Ziad Jeha, business line director, Midstream Production Systems, SLB. “Operators will be able to receive reliable and specific real-time information, allowing for focused and timely responses, especially in instances of an environmental nature.”