Unmanned technologies are taking over in the oil and gas industry, says Aeromotus

In recent years, oil and gas companies around the world and in the MENA region have been using unmanned aerial vehicles to optimise production processes and monitor infrastructure and facilities. The apparent increase in demand for the introduction of drones to inspect oil and gas facilities was noted by specialists from Aeromotus (an integrator of unmanned technologies and an official dealer of DJI) who discuss the main advantages of using drones for various purposes in the oil and gas industry.

Since the turn of the 21st century, traditional mining and production technologies have been consistently giving way to digital (automated) and robotic processes. Oil and gas exploration, well drilling, asset monitoring and operational requirements are all changing considerably.

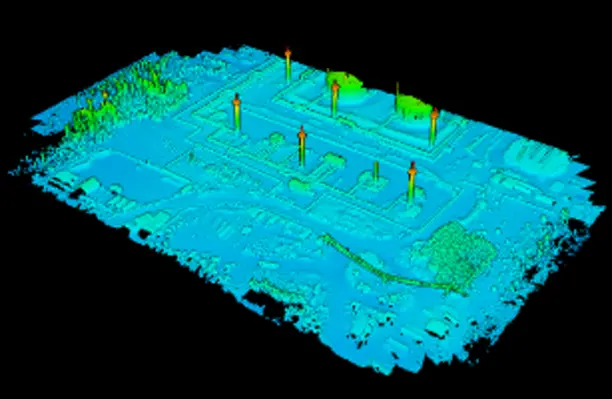

Benefits of UAV laser scanning

• Increased data collection efficiency and accuracy

• 3D documentation of the facility’s components provides a more accurate asset count

• Comprehensive datasets save time

• Improve project visualisation and collaboration

• Time and cost saving

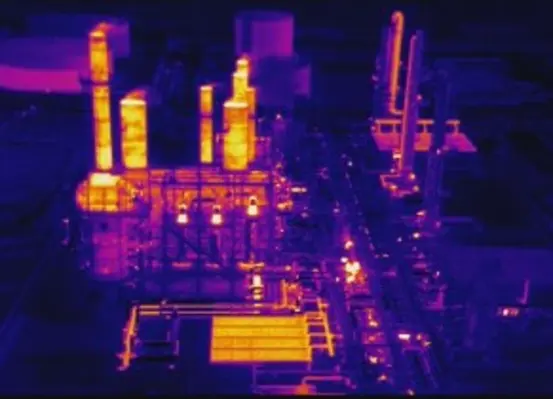

Originally used for remote asset monitoring during both regular operations and emergencies, the latest sensing and imaging technologies enable drone deployment for predictive maintenance of critical infrastructure. Drone integrators also collaborate with oil and gas firms to develop the best drone solutions. An added impulse to drone use is provided by cloud computing and the IoT. In fact, market studies reveal that the global oil and gas drone services market is expected to grow at an approximately 60.96% CAGR between 2020 and 2025.

Originally used for remote asset monitoring during both regular operations and emergencies, the latest sensing and imaging technologies enable drone deployment for predictive maintenance of critical infrastructure. Drone integrators also collaborate with oil and gas firms to develop the best drone solutions. An added impulse to drone use is provided by cloud computing and the IoT. In fact, market studies reveal that the global oil and gas drone services market is expected to grow at an approximately 60.96% CAGR between 2020 and 2025.

The combined reserves of OPEC member countries in MENA constitute approximately 840bn barrels of crude oil and 80 trillion m3 of natural gas, which is around 58% and 43% of global totals, respectively. Thus, MENA countries are at the forefront of implementing advanced technologies in these industries.

“We're rolling out AI and advanced data analytics across our biggest production facilities, deploying drones and robotics by air, land and sea, and we’re intensively researching carbon capture, utilisation and storage,” said HE Yasir Othman Al-Rumayyan, Chairman of Saudi Aramco's Board of Directors at the International Petroleum Technology Conference in 2022.

Traditional monitoring methods in the oil and gas industry are patrolling and surveying by ground teams and aerial photography from helicopters or aircraft. Their key disadvantages are high labour costs and risks to life and health. High costs lead to less frequent monitoring, thus, potentially overlooked equipment failure, pipeline rupture and leakage, etc.

UAV monitoring is growing particularly relevant: it eliminates risks to human life and health and the need to interrupt work, allows the coverage of large areas in a single drone flight, saves time and money, and enables several flights to be conducted daily.

The use of advanced unmanned technologies can replace dangerous and routine human monitoring of oil and gas facilities and expensive manned equipment inspections. Drone technology, Industrial Internet of Things (IIoT) with connected sensors and devices, digital oilfields, and digital twin technologies now allow companies to remotely monitor, and even operate, physical assets. With large-scale physical assets, often located in harsh conditions, oil and gas companies appreciate the chance to perform certain tasks remotely using smart sensors, robots, and drones. The adoption of hi-tech equipment will expand progressively in the coming years and give early adopters an edge over more conservative firms.

The tasks that can be performed by UAVs include:

• Remote monitoring & surveillance

• 3D modelling (Digital Twin)

• Methane management

• Inspection & predictive maintenance

• Material handling

• Emergency response

Aeromotus, an Unmanned Solutions integrator, will help you select UAV and payloads for specific enterprise tasks and train drone piloting and data processing specialists. In addition, they will provide technical support for the entire lifecycle of the drones.