Parker Wellbore and TDE have partnered to perform pilot projects and commercialise TDE’s proprietary tde powerline downhole power and data highway, to optimise the drilling process

They will also provide tde powerline services globally.

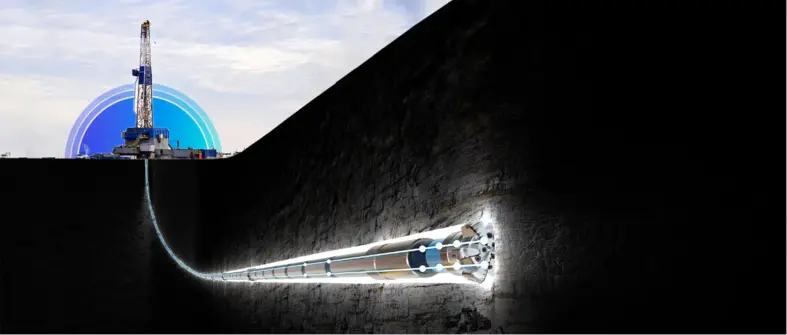

tde powerline is a downhole high power, high bandwidth data highway enabling intelligent digital drilling systems. tde powerline wired drill pipe technology provides electric power from the surface via the drill string to the BHA and greatly increases downhole data streaming while drilling to levels not seen today. The tde powerline technology delivers 300 watts of power and supports bidirectional communication at 200,000 bit/sec – nearly four times as much as current wired drill pipe data rates or 10,000 times mud pulse data rates.

tde powerline can be retrofitted to existing drill pipe with premium connections a Parker Wellbore facility or supplied as a pre-configured tde powerline drill string managed by the TDE/Parker alliance. It will help reduce NPT and improve safety by eliminating pulsers, turbines, batteries and enabling a continuous view of conditions at-bit and along-string measurements. As such it will facilitate immediate, informed, and actionable decision-making to deliver safe, efficient wells digitally and consistently, accurately and on schedule, thereby contributing to a more environmenally friendly drilling process.

Sandy Esslemont, president and CEO of Parker Wellbore, commented, “Partnering with TDE to bring tde powerline to our customers advances Parker Wellbore’s technology strategy of reducing risk and optimising performance in the drilling process. Our global network of API Q1/ISO compliant machining facilities, yard space, and our pre-eminent position in providing and servicing the industry’s premium drill pipe make us the ideal one-stop global partner to support our customers.”