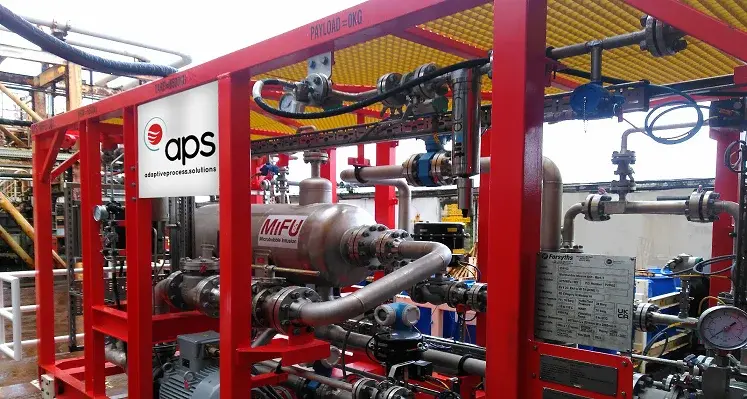

Adaptive Process Solutions (APS), a produced water treatment specialist, has completed a successful field trial of its new Microbubble Infusion Unit (MiFU) technology, which reduces oil in water (OiW) levels

Increased oil in water (OiW) levels in produced water are proving a challenge for operators. The new technology, designed as a retrofittable add-on to existing water treatment systems,was shown to achieve a near five-fold reduction in OiW levels in combination with a synergistic production chemical in the trial, conducted on an FPSO in the North Sea.

Infused micro bubbles

MiFU uses infused micro bubbles which attach to very minute particles of oil and fine solids in the produced water which can then be easily removed by the asset’s existing separator process. While underlying technologies have already been proven, MiFU is unique through its implementation of a patented multi-pass process which directly injects size and quantity-controlled gas microbubbles into target points in a contaminated water stream.

MiFU’s superior bubble saturation and variable bubble size range means it is capable of processing between 1,000 and 100,000 barrels of water a day, reducing up to 90% of oil and contaminants and eliminating the requirement for further costly downstream filtration and material management.

Paul McAlister, managing director of APS, said the MiFU was developed to address the industry-wide issue faced by operators to efficiently and effectively clean produced water so that it meets strict regulatory standards before it can be discharged back into the sea.

“This successful field trial is the culmination of four years’ research and development and MiFU is the first of its kind worldwide. We are a homegrown Aberdeen company and we have now launched a world-leading environmental technology,” he said.