thyssenkrupp Uhde, and Johnson Matthey (JM), are teaming up to offer a fully integrated low carbon (blue) ammonia solution that is more climate-friendly than current production methods

Demand for ammonia is growing because it is easier to store and transport than pure hydrogen, given it can use existing infrastructure, and is key to decarbonising the world’s power, shipping, and industrial processes.

The solution will combine thyssenkrup Uhde’s uhde ammonia process and JM’s hydrogen expertise through its LCHTM technology, which will enable the production of blue ammonia with up to 99% CO2 capture. thyssenkrupp Uhde has licensed, engineered, or constructed over 130 ammonia plants worldwide since 1928 and is market leading in plants greater than 3,000 metric tonnes per day with its unique uhde dual pressure technology. JM’s LCH technology, which utilises JM’s autothermal reformer alone, or in conjunction with JM’s gas heated reformer, has been selected for several of the world’s first large scale blue hydrogen projects.

Lucretia Löscher, COO thyssenkrupp Uhde, said, “At thyssenkrupp Uhde, we are committed to our purpose, ‘we create a livable planet’. With this strong partnership we further broaden our portfolio of climate-friendly solutions and can help our customers even better to reach their sustainability goals.”

Alberto Giovanzana, managing director – Catalyst Technologies at Johnson Matthey, said, “We know multiple routes are needed in the energy transition, and ammonia provides several options because it can be used directly in power and shipping industries, and as a hydrogen carrier to safely transport hydrogen to areas it is not easy to produce. Combining our expertise and over two decades worth of partnership with thyssenkrupp Uhde, we are excited to offer this technology which will allow our customers to produce ammonia with significantly lower CO2 emissions.”

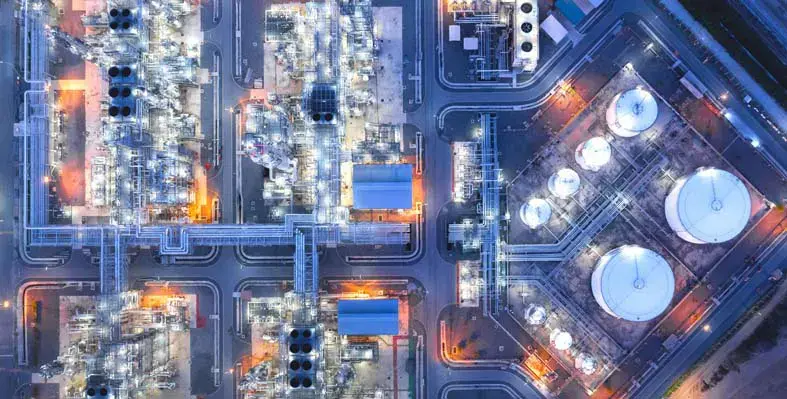

New collaboration for blue ammonia technology

The solution will combine thyssenkrup Uhde’s uhde ammonia process and JM’s hydrogen expertise through its LCHTM technology. (Image source: thyssenkrupp Uhde GmbH)