Tammam Altajar, Dennis Miguel and Rami Al Hamadah outline the benefits of TAQA’s Thruster drilling dysfunction mitigation technology

More complex wells are being drilled with sophisticated Bottom Hole Assemblies (BHA). The impact of downhole shock and vibration on drilling operations has raised awareness, and demanded more understanding of this.

Shock and vibration (S&V) is one of the issues encountered during drilling operations. It can have a significant impact on drilling operational costs and time. S&V is the main cause of Logging While Drilling (LWD) tools and Rotary Steerable Systems failures, resulting in significant cost increases. In some cases, it is the major contributor to twist-offs and back-offs. There are no statistics that quantify the impact of S&V on drilling costs. However, a study indicated that a 10% rise in drilling costs is due to drilling string S&V.

S&V are the result of the nonlinear interaction forces between the bit & drill string with the formation and the wellbore, and exist in three different modes, axial, lateral & torsional. Axial is the up and down motion along the drill string axis, also known as bit bounce. Lateral is perpendicular to the drill string axis, bit or BHA whirl is a common mode of lateral vibrations. Torsional is an irregular rotational motion known as stick-slip; it also includes High-Frequency Torsional Oscillation (HFTO). Most of the time, those vibration modes will be coupled with each other in the downhole drilling environment. S&V can occur due to different reasons such as bit and formation interaction, bit compatibility with the application, operating at BHA critical RPM, stabiliser design, wellbore rugosity, etc. S&V could be axial, lateral, torsional, or HFTO in any combination.

Many downhole tools have been developed to mitigate different vibration modes. Utilisation of these tools has been increasing over the years due to the increased awareness of the impact S&V might have on drilling operations and the necessity to prevent it.

One added value of preventing and mitigating S&V that often gets overlooked is the improvement in Rate of Penetration (ROP). In a S&V environment, part of the input energy is lost due to these vibrations, hence less energy is converted to ROP. When S&V are reduced, less energy is lost by the system, and more is directed toward drilling resulting in ROP improvement.

TAQA has several drilling dysfunctions mitigation technologies and one of them is the Thruster. Below, the Thruster operation is explained and some case studies are discussed to demonstrate the impact of the Thruster in reducing S&V and improving ROP when used in the right application.

Technology description

The Thruster is an innovative technology designed to revolutionize drilling operations by effectively managing weight on bit and differential pressure. It maintains constant bit engagement, consistent parameters, and reduces the impact of non-uniform motions in the drill string, ultimately enhancing drilling efficiency and minimizing the risk of damage to downhole components.

Key benefits

1. Bit engagement: Utilising pump open force, the Thruster prevents bit bounce and stick-slip motions, ensuring continuous engagement with the rock formation.

2. Drilling consistency: Consistent parameters lead to increased efficiency across various drilling metrics, from ROP to torque and differential pressure.

3. Shock and vibration reduction: By maintaining consistent parameters, axial shock and stick-slip motions are minimised, promoting smoother drilling operations.

Reliability features

1. Simple and robust design – fully mechanical.

2. Three temperature seal options: Standard (up to 250°F), Hot Hole (up to 400°F), and Geo (up to 450°F)

3. Minimal pressure drop due to its full bored internal diameter.

Functional characteristics

1. Utilises a single spring stack that supports both tension and compression, providing flexibility in placement and effective performance at low WOB.

2. Balances pump open force and WOB to maintain constant bit engagement.

3. Engineering support to ensure optimal performance.

Customisable spring stack

Based on the drilling parameters expected, the spring stack can be tailored to any application, making it suitable for various well types, from large ID vertical wells to slim ERD lateral wells.

Efficacy and cost savings

The adoption of Thruster technology has demonstrated remarkable efficacy in delivering substantial cost savings by minimising downhole dysfunctions, reducing downtime, and curbing the need for expensive trips out of the hole and repairs to downhole components.

Versatility and adaptability

Its adaptability makes it an invaluable asset for diverse drilling scenarios, empowering operators to optimise performance across varying drilling environments.

Case studies

In the Middle East, drilling through carbonate reservoirs can be quite a challenge due to high shock and vibration, often leading to downhole tool failures or compromised drilling efficiency. This case study focuses on wells with an 8.5-inch hole section. The primary goal is to successfully drill the 8.5-inch hole section in one run, including a vertical, curve, and lateral section, with a total length exceeding 8,000ft.

The field challenges include drilling with losses, high gas peaks, wellbore instability, and high dogleg requirements to land the well. With hundreds of wells in the project, extensive best practices and lessons learned have been applied, pushing the technical limits of drilling. This encompasses well-defined trajectories, targets, casing points, and various BHA components such as Bits, RSS, MWD, LWD, stabilisation, and flexibility. Despite advancements in drilling technology, downhole tool failures continue to significantly impact operations, leading to non-productive time and compromised drilling efficiency.

To address these challenges, the solution involves using the Thruster to dampen vibration and enhance drilling parameters for improved performance.

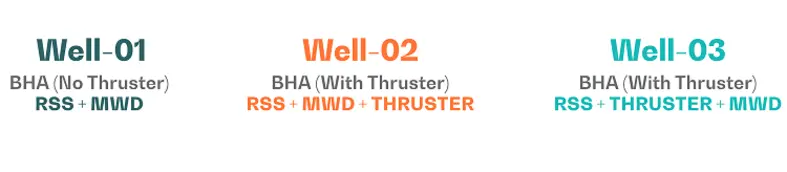

Establishing a baseline, three wells with similar directional companies, drilling fields, and well profiles have been chosen for comparison.

Results

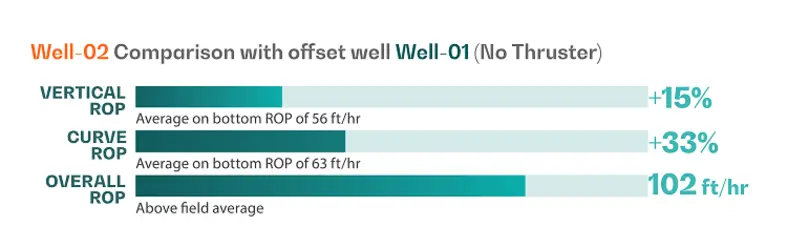

The drilling performance of Well-01 has been the baseline KPI for the operator, but Well-02, with a Thruster placed above the MWD, has shown significant improvement. It successfully drilled the entire 8.5” hole section in one run, covering vertical, curve, and lateral sections. The chart below illustrates the enhanced ROP, attributed to the ability to apply more drilling parameters, thanks to reduced shock and vibration.

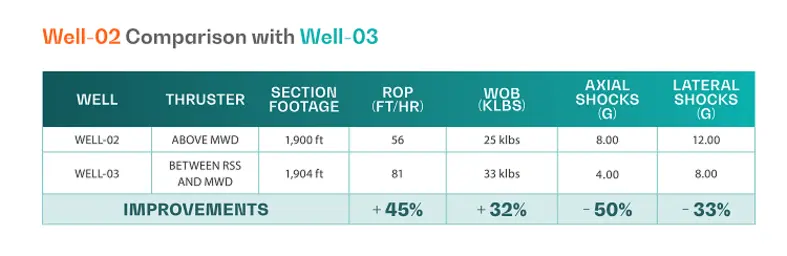

The drilling operation for Well-03 utilised the same profile as Well-01 & 02, with the Thruster strategically positioned between the RSS and MWD. The directional company harnesses wireless technology to transmit signals between these tools, allowing for the placement of the Thruster closer to the bit. This innovative approach significantly reduces shocks and vibrations, leading to exceptional vibration dampening and record-breaking ROP. The placement of the Thruster above the RSS and closer to the bit enabled the application of more drilling parameters, resulting in improved performance. The table below shows a detailed overview of the significant reduction in shocks and vibration.

Summary

In the case study, the three wells displayed a range of well profiles, from vertical to curve to lateral. The inclusion of the Thruster in the BHA has been proven to effectively reduce drilling shocks and vibration. Placing the Thruster closest to the bit has the most significant impact on shock and vibration mitigation.

Impact of the Thruster for operators:

- Reducing the risk of downhole tool failure by operating the tools at very low shocks and vibration.

- Lower drilling vibration allows for the application of higher drilling parameters, directly improving the drilling ROP. Faster ROP results in reduced drilling time.

Impact of the Thruster for directional companies:

- Reduced shock and vibration lead to fewer downhole tool failures, thereby increasing service quality KPI.

- Reduced tool failure decreases damage costs and prevents financial losses due to NPT contractual impact.

- Decreased cumulative shocks and vibration result in reduced maintenance costs.

- Reduced shocks and vibration enhance the directional steerability of the RSS, improving drilling efficiency by eliminating the need to control parameters.

The Thruster technology is designed with axial functionality, but actual data shows that it not only mitigates axial vibration but also other types of vibration, such as lateral and high frequency vibration.

In conclusion, the Thruster technology offers a ground-breaking solution for optimising drilling operations in the oil and gas industry. It effectively mitigates axial dysfunctions, curtails downtime, and amplifies drilling efficiency, with proven cost savings and enhanced safety, making it a transformative technology in the drilling industry.

References:

SPE SPE-210569-PA: Analysis of Whirl Characteristics of Drill String Under Multidirectional Coupling Conditions (Jialin Tian et al. 2022).

Leine, R. I., Van Campen, D. H., and Keultjes, W. J. G. 2002. Stick-Slip Whirl Interaction in Drillstring Dynamics.