Energy services provider Expro (NYSE: XPRO) is leading industry efforts to meet environmental targets with the development of a digital technology that can help drilling contractors and operators cut an estimated 146 tons of CO2 emissions annually – the equivalent of 58 transatlantic flights

While the oil and gas industry has introduced many digital innovations, tubular running services (TRS) is an area which has historically lagged. Expro, however, is driving greater rig floor automation thanks to its iTONG system. In addition to cutting emissions, the iTONG system is designed to help protect personnel and is estimated to save operators nearly 50 hours of rig time and US$2mn annually, per installation.

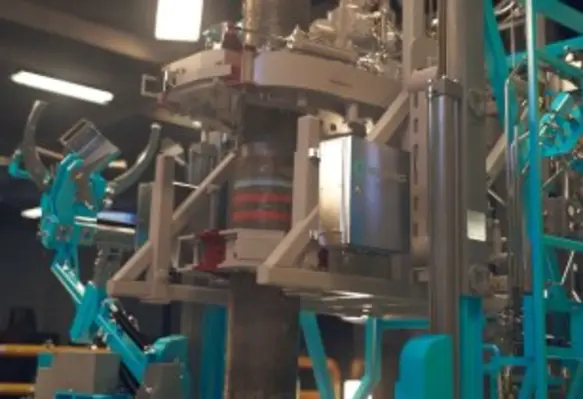

The iTONG system is the industry’s most technologically advanced, single-push button tubular make-up solution which allows the operator to control, execute, verify and validate every connection make-up via a tablet or their control chair. It ensures joints of casing and tubing can be made to a specific torque, or broken out in an automated sequence.

With a reduction in the number of personnel required for tubing operations, a rig using iTONG can reduce annual emissions from rig time, travel and accommodation by an estimated 146 tons a year – the equivalent of removing 58 10-hour flights from Oslo to Houston over the course of a year.

Jeremy Angelle, vice-president, Well Construction, said, “iTONG offers seamless integration into existing automated rig operations and marks a key step toward fully autonomous tubular running. Digital solutions are increasingly being deployed to enhance operations, improve reliability for well integrity, and reduce personnel on the rig floor, which is resulting in improved safety and efficiency, with lower operational costs across the industry.

“Some 47% of our R&D spend is directly allocated to carbon reduction projects, which shows our dedication to helping energy companies hit their targets.”

The technology has undergone significant field trials on a high-efficiency jack-up rig in the North Sea, taking part in 22 jobs, resulting in more than 1,600 connections being made. Also, iTONG is coupled with Expro’s iCAM torque-turn tubular connection make-up system, which uses artificial intelligence to make data-driven decisions, ultimately determining whether the make-up has been successful.