DNV has awarded the full certification to Strohm and Evonik, attesting that the unidirectional Carbon Fibre PA12 tape ‘VESTAPE PA12-CF’ (PA12) used for Strohm’s thermoplastic composite pipe (TCP) is fit to use for dynamic sweet and sour hydrocarbons, water and gas injection applications according to DNV-ST-F119

The two companies, in partnership with the Netherlands Aerospace Centre (NLR), have led the way in the development, qualification and supply of PA12 for TCP applications following an intensive investment and testing programme over the past five years.

The novel knowledge-based approach introduced in DNV-ST-F119 and fully utilised by Strohm and Evonik has been trailblasing in seeking a fundamental understanding of the material to demonstrate the lifetime performance of a product operating in a challenging chemical, thermal and mechanical environment.

NLR provided the main composite testing facilities which allowed parallel dynamic and long-term testing, thus speeding up the process significantly compared to traditional sequential testing.

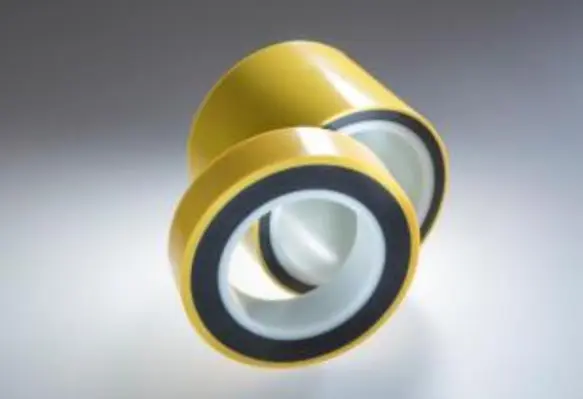

PA12 is a fully non-metallic, corrosion-resistant solution. Due to the use of carbon fibres, it is exceptionally resistant to fatigue-based failures, marking it a perfect choice for any dynamic application from jumpers to flowlines and risers, including sweet and sour hydrocarbon, water and gas service.

Alexandre Paternoster, material technology team lead at Strohm, said, “Our fully non-metallic solution for load-bearing structures shows great potential to meet any challenges that corrosive environments can bring. Being applicable to both static and dynamic mode in hydrocarbon offers a great variety of addressable applications, including flowlines and risers.”

Carsten Schuett, industrial and energy technology leader at Evonik, added, “The full application of the DNV’s standard’s approach to qualify the material has only added to the complexity but, with the help of our partners, we finally succeeded in characterising the material in unprecedented detail and unlocked its full potential.”