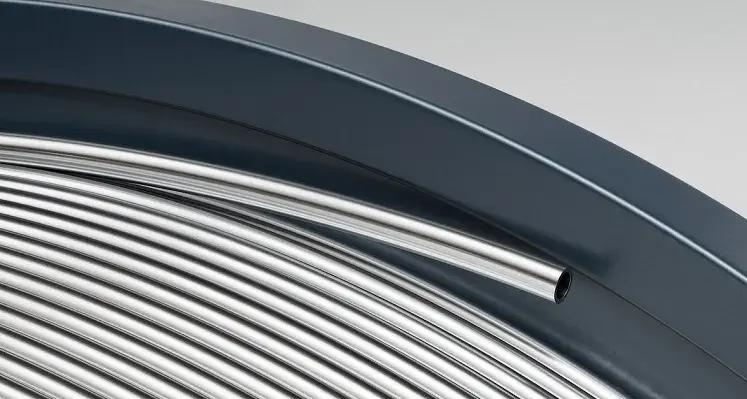

Alleima has launched SAF 3007, a new super-duplex stainless steel grade developed for subsea umbilicals, which builds and improves on SAF 2507, the current standard, in terms of weight, strength and efficiency

With superior strength, fatigue properties and excellent corrosion resistance, SAF 3007 is ideally suited to harsh deepwater environments.

Tom Eriksson, executive vice president and head of R&D at Alleima, said, “The launch of SAF 3007 marks the next step in our duplex evolution, fulfilling customer demands for a next generation umbilical tube with less material and thinner walls.

“As the market leader in umbilical steel tubing, we often get requests for a material matching SAF 2507 in reliability, but with reduced costs, improved fatigue life and enhanced pressure handling,” added John Tokaruk, global product manager for umbilical tubing at Alleima. “SAF 3007 (UNS S83072) accomplishes all this with a ‘less is more’ approach. Thinner tube walls, thanks to its superior strength and fatigue properties, results in lower cost per meter. It offers the excellent corrosion resistance of SAF 2507, and a similar microstructure, as well as simplified welding.”

Properties for harsh deepwater environments

SAF 3007 features additional chromium, reduced molybdenum and, for the first time, tungsten, which maintains the corrosion resistance after welding. Together, these properties are ideal for subsea umbilicals in chloride-rich environments.

SAF 3007 will be available in a broad range of sizes by the end of 2024.