DNV has announced a new recommended practice, designed to cut costs and improve efficiency in parts management in the energy sector

In the fast-moving landscape of industrial operations, maintaining secure access to necessary parts is a significant challenge. Traditional inventory systems often result in overstocking or stockouts, leading to inefficiencies and increased costs. Digital inventories — virtual repositories that enable on-demand production using AM and other near-net-shape (NNS) technologies, offer a transformative solution. By prioritising the development of critical digital parts, companies can efficiently allocate resources and respond swiftly to market demands.

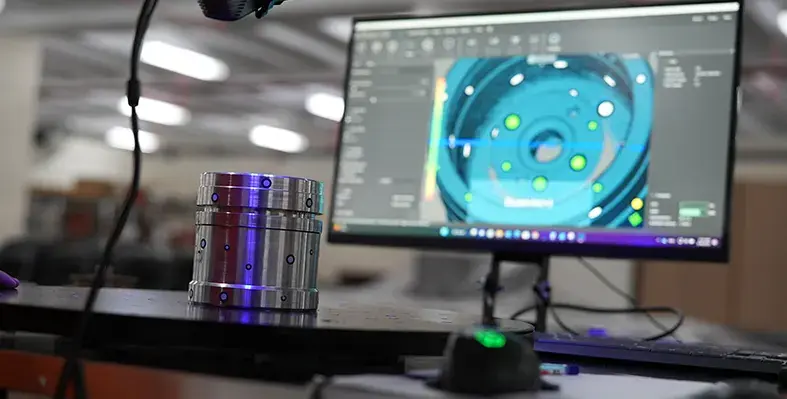

The DNV-RP-B205: Digital inventories and on-demand manufacturing framework helps the sector assess the maturity of a digital part, from initial design or data capture to qualification and production. The process includes 3D scanning, capturing design data, generating engineering documentation, and preparing order-ready parts through on-demand manufacturing.

Additive manufacturing (AM) is a key part of this strategy, as it produces components close to their final specifications.

Key advantages include:

- Reduced storage costs: Digital inventories minimise the need for physical storage space.

- On-demand production: Parts can be manufactured as needed, reducing lead times and the risk of obsolescence.

- Customisation: AM and NNS technologies enable the production of parts tailored to specific requirements, enhancing performance and reliability.

- Supply chain resilience: Multiple sourcing options and production routes enhance supply chain security, mitigating potential disruptions.

Prajeev Rasiah executive vice president & regional director, Energy Systems, Northern Europe at DNV said, “The integration of digital inventories with on-demand production using additive manufacturing and near-net-shape technologies is a game-changer for the energy industry. This innovative approach offers a sustainable and agile solution to spare parts management, enabling companies to reduce costs, improve efficiency, and enhance asset reliability. With DNV’s recommended practice, DNV-RP-B205, the path to digital part readiness is clearer, paving the way for broader adoption.”

DNV recommended practice to transform digital parts management

The readiness levels defined in DNV-RP-B205 allow companies to scale up digital inventories quickly and cost-effectively. (Image source: DNV)