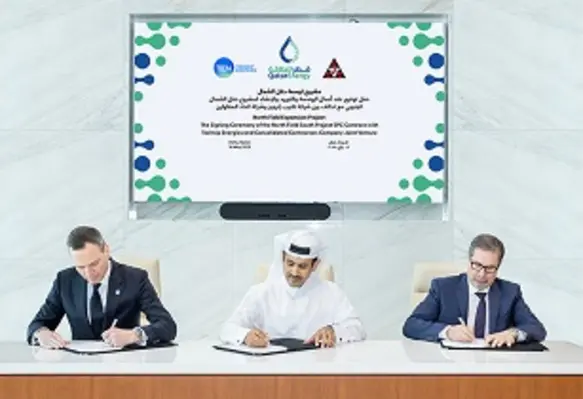

QatarEnergy has awarded an engineering, procurement, and construction (EPC) contract for the North Field South (NFS) project worth around US$10bn to a joint venture of Technip Energies and Consolidated Contractors Company (CCC)

The contract comprises two LNG mega trains with a combined capacity of 16 mn tons per annum (MTPA), with associated facilities for gas treatment, natural gas liquids recovery, as well as helium extraction and refining within Ras Laffan Industrial City.

NFS, together with the North Field East (NFE) project, will increase Qatar’s LNG production capacity from the current 77 MTPA to 126 MTPA. QatarEnergy holds a 75% interest in the NFS project and has already signed partnership agreements with TotalEnergies, Shell, and ConocoPhillips for the remaining 25%.

HE Saad Sherida Al-Kaabi, Minister of State for Energy Affairs,the president and CEO of QatarEnergy, said, “QatarEnergy is proud to announce yet another significant milestone in the world’s largest LNG project, reinforcing our commitment to meeting the global demand for natural gas.

“The NFS project is a unique development that minimises its environmental footprint by design. It includes one of the largest CO2 capture and sequestration facilities and constitutes an important step towards achieving QatarEnergy’s target of more than 11 MTPA of CO2 capture and sequestration by 2035."

In addition to the carbon capture and sequestration facilities, the environmental attributes of the NFS project also include importing a significant portion of the project’s electrical power requirements from the grid in the form of renewable solar power, which will be generated at QatarEnergy’s solar power facilities currently under construction in Ras Laffan Industrial City. It also includes a 'jetty boil-off gas' recovery system, which will help reduce greenhouse gas emissions. The project will conserve five million cu/m of water per year by recovering 75% of the plant's tertiary water. Nitrogen Oxides (NOx) emissions will also be minimised through the application of enhanced Dry Low NOx technology.