How advanced diagnostics systems can reduce the carbon-per-barrel overhead

Demand for energy is rising and, despite the growth in renewables, oil and gas will form a crucial part of the global energy mix for many years to come. In the upstream industry, we have a responsibility to reduce emissions and minimise carbon footprint by maximising the efficiency of our operations.

TGT Diagnostics can help operators reduce their carbon footprints and enable the industry to deliver energy in a much cleaner way.

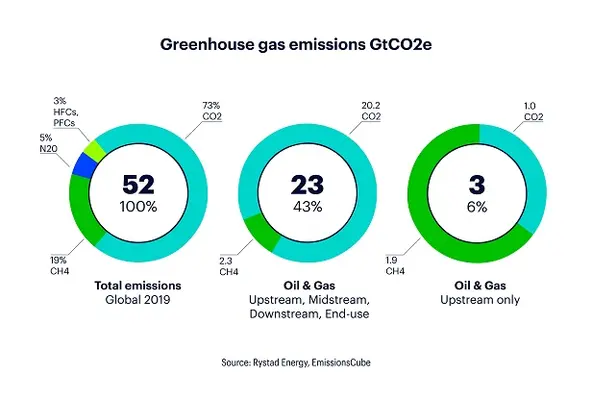

Each barrel of oil or gas equivalent produced has a carbon cost. This comprises emissions from the energy required to produce it and any gas flaring or leakage from well infrastructure that occurs during production. Energy from turbines and diesel engines accounts for more than 70% of the carbon dioxide (CO2) emissions from upstream operations. In 2019, upstream activities accounted for approximately 6% of total annual greenhouse gases produced by human activity and the “carbon per barrel” overhead was about 48 kgCO2e per barrel equivalent. Making substantial and sustained reductions to this figure will help in the battle against runaway climate change. Therefore, enabling operators to achieve this goal is a primary aim for TGT.

How can companies tackle this issue? Having a better understanding of the dynamic behaviour of well systems is the starting point for increased efficiency and reduced emissions. Applying advanced, through-barrier diagnostics helps operators see beyond the wellbore. This provides them with the insights they need to adopt reservoir, well and production strategies that reduce energy use and emissions.

How can companies tackle this issue? Having a better understanding of the dynamic behaviour of well systems is the starting point for increased efficiency and reduced emissions. Applying advanced, through-barrier diagnostics helps operators see beyond the wellbore. This provides them with the insights they need to adopt reservoir, well and production strategies that reduce energy use and emissions.

Accurate diagnosis is the key

TGT Diagnostics’ systems help operators and regulators achieve their net-zero targets by revealing inefficiencies in energy-intensive operations and locating sources of greenhouse gas emissions.

Effective through-barrier diagnostics can help operators identify and address a wide range of energy inefficiencies. For example, the water injection pumps used to maintain reservoir pressure are a major contributor to upstream energy demand. Integrity issues can divert water from the intended reservoir target, thereby increasing the volume of water needed, extending pumping requirements and wasting energy resources. Through-barrier diagnostics can reveal diverted water behind casing, help operators to apply fast and effective remediation methods and, ultimately, reduce injection rates and associated emissions.

Our industry has a vital role to play in the drive to achieve a low-carbon future. We can start to deliver energy in a much cleaner way by minimising the carbon footprint of upstream operations.