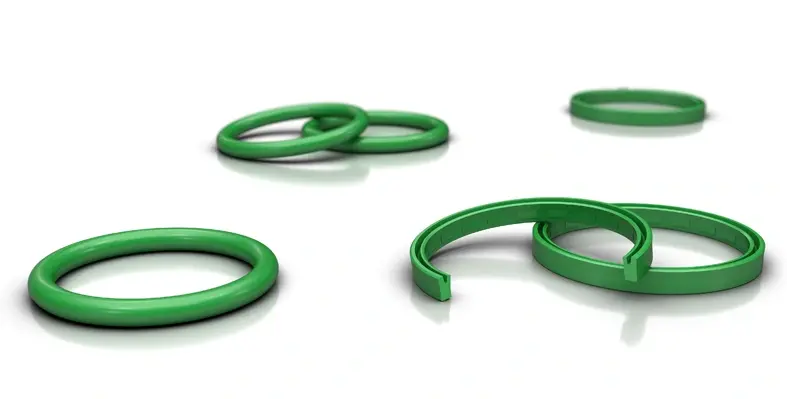

Trelleborg Sealing Solutions has launched the full H2Pro range of more than 20 sealing compounds for every application of the hydrogen value chain, from production to transport and storage and end-use

Proven to withstand challenging application environments, the materials are suitable for high pressures, low temperatures, and resist permeation, making them better able to withstand rapid gas decompression (RGD), while also demonstrating excellent wear and extrusion properties.

James Simpson, global segment director energy, said, “As the smallest and lightest molecule, hydrogen has the potential to drive the energy transition, but it is difficult and complex to seal.

“The lack of relevant industry standards to validate our materials against was a major challenge when developing the H2Pro range. Some in the nascent hydrogen industry rely on standards used typically for high-pressure gasses in the oil and gas sector, but these are often unsuitable for replicating real-world hydrogen application conditions.

“Trelleborg has developed proprietary testing protocols that replicate real-world hydrogen applications, providing customers with confidence in products to make the energy transition reliable, efficient and economic.”

Trelleborg's proprietary test standards cover hydrogen permeation, endurance validation and hydrogen compatibility, including the ability to withstand rapid gas compression (RGD). Occurring when hydrogen permeates into a seal under pressure, RGD can cause seals to blister and crack when pressure is rapidly relieved.