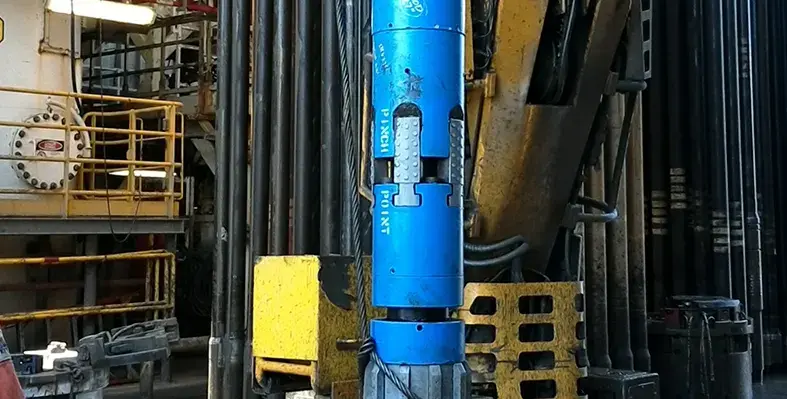

Key energy industry use cases enabled by IoT Nano include pipeline monitoring. (Image source: Adobe Stock)

Viasat a global leader in satellite communications, has launched its next generation IoT Nano connectivity service to deliver powerful, two-way messaging connectivity even in the most remote and challenging environments

IoT Nano is designed to meet growing global demand for cost-effective, low-data, low-power, Internet of Things (IoT) services across remote and challenging environments where mobile connectivity is often required. It enables organisations to effectively monitor and control fixed and mobile assets with ultra-reliable satellite coverage, especially in geographically dispersed, isolated, or hard-to-reach areas where terrestrial networks are limited or non-existent, through Viasat’s global L-band network.

Powered by ORBCOMM’s next-generation satellite IoT service, OGx, IoT Nano offers faster message delivery speeds, larger message sizes, and new hardware options, unlocking near real-time visibility and situational awareness and richer, more actionable data for energy operations even in remote locations.

Use cases

Key energy industry use cases enabled by IoT Nano include:

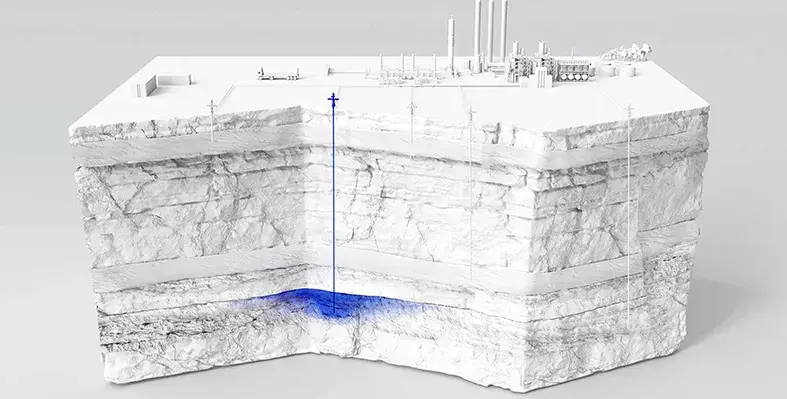

• Asset tracking: Monitoring the location and movement of valuable equipment and vehicles across vast operational areas (e.g., pipelines, machinery, fleets).

• Pipeline monitoring: Detecting anomalies, leaks, and ensuring the integrity of critical oil, gas, and water pipelines.

• Security: Enhancing surveillance and access control for remote utility and oil & gas sites, including wellheads, substations, and pumping stations.

• Tank level monitoring: Managing levels in storage tanks for oil, gas, and water, optimising supply chain and preventing overflows.

• Telemetry: Collecting and transmitting vital operational data from remote sensors and devices for real-time insights and predictive maintenance.

• Remote site monitoring: Gaining visibility into the status of pumps, generators, and other critical infrastructure in isolated locations.

Andy Kessler, vice president, Enterprise and Land Mobile, Viasat, said, "The IoT Nano service represents a significant advancement in providing flexible, scalable, and energy-efficient IoT connectivity to businesses operating in the most remote corners of the world. By leveraging the enhanced capabilities of the ORBCOMM OGx service and equipping our partner ecosystem with new low-cost modules and service capabilities, we are empowering customers with access to smarter data, more frequently, in more places, at a lower cost."

“OGx delivers faster speeds, larger messages, and lower power usage, all backed by ORBCOMM’s proven terminals, network, and field support,” said Dave Roscoe, president of Satellite IoT at ORBCOMM. “By lowering the cost and increasing the effectiveness of satellite connectivity, OGx makes it possible for our partners to enter new markets, expand use cases, and drive incremental growth.”