As we drill deeper and utilise enhanced recovery methods such as thermal and CO2 injection, we are exposing the products in our pipelines to greater concentrations of harsh chemicals, higher temperatures and higher pressures

In addition, it is estimated that 40 per cent of the world’s remaining gas reserves are sour, and CO2 and/or H2S content within these wells averages 10 per cent or more.

Maintaining pipeline integrity and keeping emissions in check has never been more important. Yet, traditional pipeline materials, including Phenolic and GRE isolation gaskets, are not always up to the challenge.

Something needed to change.

January 2020 saw the introduction of the EVOLUTION® Isolating gasket (Kit) the best available technology. EVOLUTION®, a fully-encapsulated isolation gasket that delivers the impermeable performance needed to prepare any flange for the increasing risks found in today’s oil and gas industry.

Unlike GRE gaskets, which are prone to delamination, EVOLUTION® has no laminations and as a result can better withstand high-pressure environments.

Featuring a thinner, 1/8” design, EVOLUTION minimises the difficulties often encountered when attempting to install thicker isolating gaskets. The full-coating encapsulation allows the gasket to be hydrotested and left in the pipeline with the same isolation properties as before it was tested.

Featuring a thinner, 1/8” design, EVOLUTION minimises the difficulties often encountered when attempting to install thicker isolating gaskets. The full-coating encapsulation allows the gasket to be hydrotested and left in the pipeline with the same isolation properties as before it was tested.

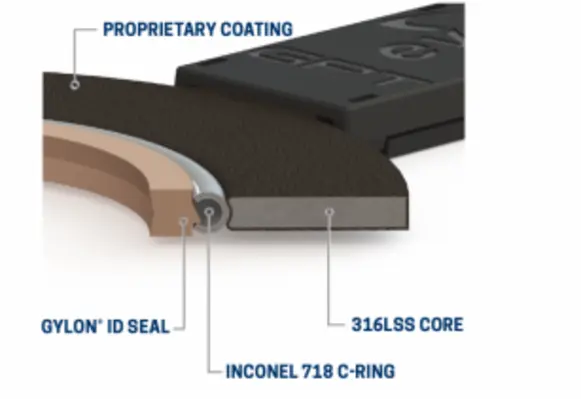

EVOLUTION’s coating (a GPT proprietary material) is extremely abrasion and impact resistant while providing chemical resistance to H2S, steam, CO, CO2 and other chemicals often found in oil and gas pipelines. This fully encapsulated coating also prevents the need for expensive exotic cores, as it eliminates contact to exposed metal.

The EVOLUTION gasket features the highest tightness parameters for any product available in the market today. With demands placed on the oil and gas industry to improve leakage rates, the increased levels of tightness achieved will exceed requirements and result in greater joint integrity.

An acceleration in H2S levels as operators drill deeper and more aggressively causes traditional GRE products to become vulnerable over time. Through extensive testing EVOLUTION has demonstrated virtually no permeation or degradation, eliminating this costly problem.

EVOLUTION provides the highest pressure rating of any isolating gasket available. Unlike GRE gaskets, which are prone to delamination, EVOLUTION has no laminations and as a result can better withstand high-pressure environments.

Rated to 500°F (260°C), EVOLUTION can operate under high temperatures. Tested comprehensively for safety, the product has API 6FB, 3rd Edition Fire Test recognition.

“As its name implies, EVOLUTION® is the next step in gasket technology and is poised to eliminate a number of issues that plagued gaskets in previous iterations,” said Tim Hurley, GPT senior global product manager. “EVOLUTION® was designed to take the best available technology for pipeline isolation and incorporate all of these benefits into one comprehensive product.”

For more information on EVOLUTION® please visit; www.gptindustries.com/evolution