Peter Mannion, GPT Industries’ director for oil and gas, discusses how the company has been at the forefront of design and innovation for many years with Isolation products in and around the offshore oil and gas environment

In 2009, there was a planned development of a major oil field in the Deepwater Gulf of Mexico which was originally discovered in 1998 some 200 miles south into the Gulf of Mexico.

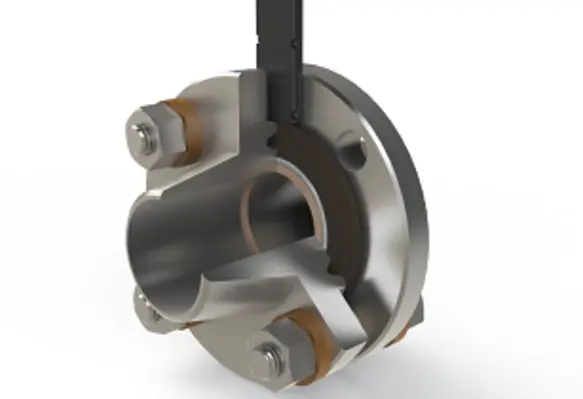

This field was thought to hold one billion barrels of oil in place and so production began in 2005 from the original truss spar. At that time the latest technology in isolation was utilised which was the ID Seal Isolation kit designed to prevent the core material of the isolation kit from being attacked by the increasingly aggressive media’s that were starting to become more prevalent.

As the search for more productive fields was underway, it was discovered that the field had up to four mboe and the extension would have the ability to produce an additional 140,000 bopd from fourteen wells.

In 2015, the decision was confirmed to extend the access to the field, and the end-user gave the green light to proceed with the project, and the contract was awarded to the engineering, procurement and constructor (EPC) firm in Korea. During the front end engineering development (FEED) stage at all the EPC’s, as well as at the end users, GPT introduced the EVOLUTION Isolation Kit emphasising the numerous advantages.

At the same time, the company received a request from an EPC working on a construction planned for the Arabian Gulf for a fire-safe isolation kit on the compressor systems on the platform.

Their overriding criteria were for fire safety, higher temperature, a three mm thick gasket and for complete protection from the aggressive saltwater conditions. The sour conditions were listed as extremely sour and therefore, the highest levels of protection against sour media were required. Dealing with major engineers in the Middle East over the last few years GPT had become very aware of the escalation of Hydrogen sulfide (H2S) levels in the oil and gas fields as the operators utilise new technology to extract oil from the previously inaccessible fields.

The EVOLUTION system met all the above criteria and was supplied for the compressors and associated piping section on the platform which was destined for the Persian Gulf off Abu Dhabi.

The EVOLUTION system met all the above criteria and was supplied for the compressors and associated piping section on the platform which was destined for the Persian Gulf off Abu Dhabi.

The same criteria were of appeal to engineers working on the Gulf of Mexico project and having the ability to have one gasket in use across the platform, which also utilised the ID Seal technology. The EVOLUTION platform for Isolation gave the following advantages to this high technology project. Engineers wanted to use the ID Seal as it was already proven as a preventative measure against aggressive media, a one size fits all circumstance, a gasket as well as an isolation kit and a fully encapsulated fire-safe approved isolator.

Initially, the EVOLUTION gasket was utilised on the Cupro Nickel pipeline firefighting system purely as a seal. The main advantage being the low bolt load requirement for sealing with the seal so close to the bore which aids sealing on the soft flange material.

Then it was utilised as an isolation kit on the pipeline systems and finally as an exchanger vessel gasket.

One of the main advantages was that the gasket and kit was the same dimension as any standard gasket and therefore special design considerations for the isolation kits was unnecessary. This is the case for the traditional VCS style kits which are 6.2mm thick and do not conform to standard pipeline design software criteria.

Clearly, in terms of design and functionality, the EVOLUTION system has given engineers the ability to meet the ever-increasing demands of the field and looks likely to transform the face of pipeline isolation in the future.