GPT has long experienced issues with Glass Reinforced Epoxy (GRE) based gaskets used in steam applications

The term, ‘steam’, used in the context of this article, is intended to be broad and can mean any variation where a sub or superheated water is present as either the partial or main component makeup of the service media.

While GPT does not recommend GRE based gaskets for steam applications of any variety, these style gaskets sometimes find their way into a service where steam is present. The consequences can be a costly replacement of the gasket just months after installation, at best or catastrophic failure of the gasket resulting in a system shutdown, at worst.

The problem with GRE, when exposed to steam, is a chemical degradation process, known as hydrolysis, which takes place with the epoxy resin. The word hydrolysis comes from Ancient Greek hydro-, meaning ‘water’, and lysis, meaning ‘to unbind’. A hydrolysis reaction is a reaction involving an ester link, such as that found between two amino acids in a protein.

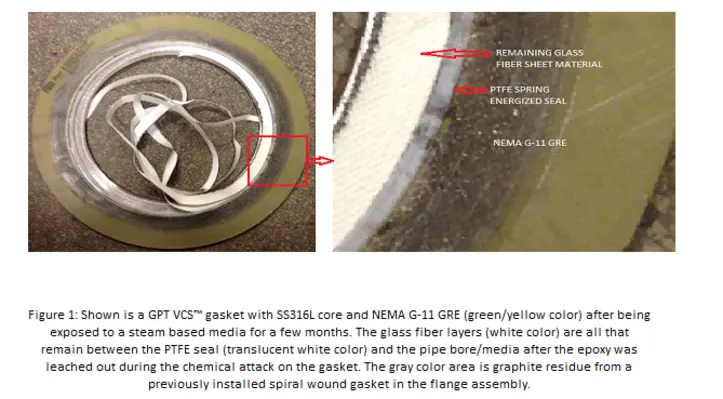

The products that result include one that receives the hydroxyl (OH) group from the water molecule and another that becomes a carboxylic acid with the addition of the remaining proton (H+). In laymen’s terms, this means that the heated water molecules in steam chemically attack the ester links in the epoxy resin; therefore, eating away at the epoxy resin. This leaves only the glass fibre layers of the GRE sheet material behind. An example of this can be seen in figure 1.

GRE gaskets have been used in water service for over 40 years with little to no degradation to the epoxy. This is because a typical water absorption value for a GRE gasket is 0.10% per the ASTM D570 test method. The majority of water applications experience service conditions of low pressures at relatively low temperatures. This is why the Linebacker style GRE gasket has been successfully used in the water market for many years.

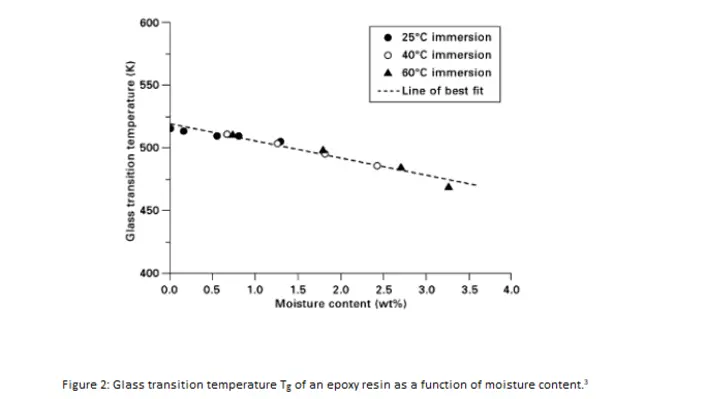

However, the effects of hydrolysis start to begin as the temperature is increased. Figure 2 shows the effect of moisture content on (glass transition temperature) Tg for a glass fibre-reinforced epoxy system that has been immersed in distilled deionised water for prolonged periods of time at three different temperatures.

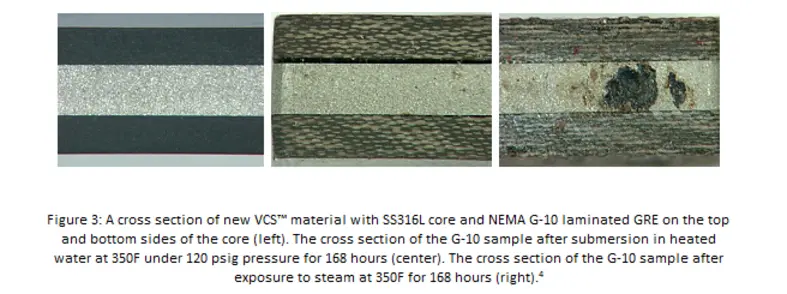

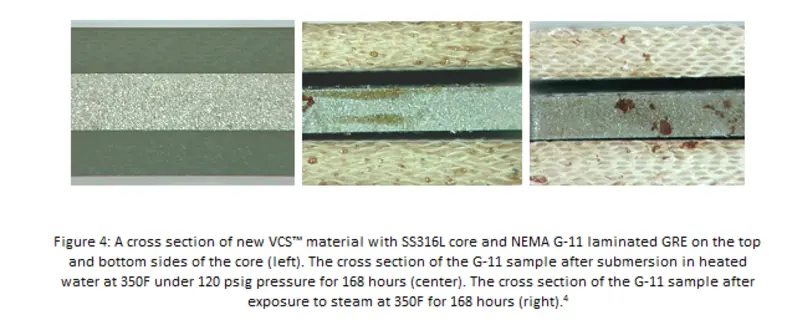

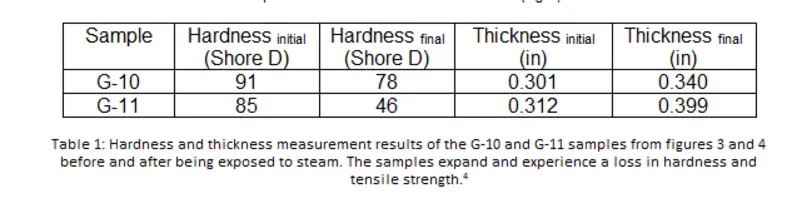

As temperature increases, the epoxy resin begins to leach out of the glass fibre sheet material. The process of hydrolysis and leaching can occur as low as 60C (140F), and it may take months to even a few years for the material to be fully saturated by the slow moisture absorption rate. This process begins to occur quicker as temperature and exposure time are increased. For applications involving steam, which typically involve higher operating temperatures, failure of a GRE based gasket can occur in as little as a few months into operation. The results of exposure to steam are seen in the images of figures 3 and 4. Measurements of these samples are shown in table 1. As the epoxy leaches out of the glass fibre layers, the GRE laminate material begins to disbond from the SS316L core.

It is important to recognise applications where elevated temperatures and the production of superheated water and/or steam are present to avoid the use of a gasket that would leave GRE exposed to the media. GPT has developed products such as the VCS-ID gasket and the new Evolution gasket to overcome the limitations of GRE in steam applications.