To overcome the limitation of injection control devices (ICDs), Tendeka, a global specialist in advanced completions, production solutions and sand control, has developed FloFuse, a new autonomous injection control device (AICD)

Traditionally, ICDs with isolation packers are installed along the lower completion string to mitigate the effect of frictional losses and isolate thief zones in horizontal water injection wells. However, distributing flow and identifying thief zones in complex heterogeneous reservoirs is problematic. Non-optimised completions result in poor water placement and ineffective sweep that may create short-circuit pathways from injector to producer, resulting in early water breakthrough in the production well.

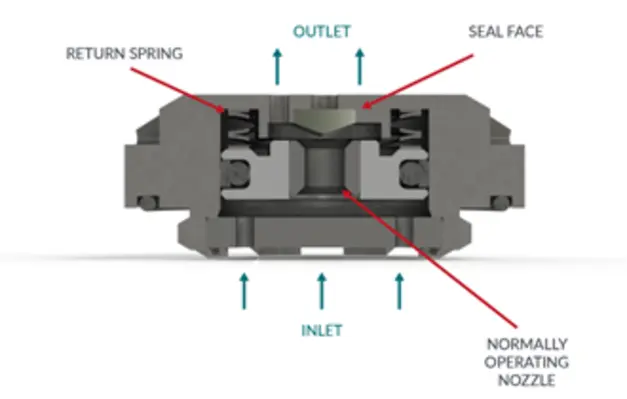

As a bi-stable valve, FloFuse (Figure 1) restricts the injection of fluid into dilated/propagated fractures and mitigates the disproportional injection of fluid into a thief zone. Importantly, this technology functions entirely autonomously providing a more cost-effective solution than alternative completions requiring intervention or surface-controlled valves to achieve the same outcome.

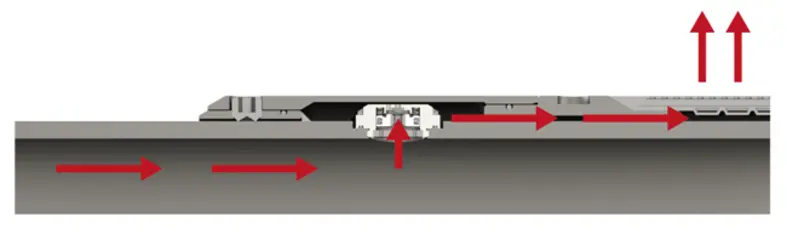

FloFuse devices are installed along the length of the reservoir and are compartmentalised using zonal isolation devices where they initially operate as passive ICDs if no thief zones are encountered. If a trigger flow rate is exceeded, the outflow is strongly constrained into the ‘fused’ zone enabling injection to be distributed among the valves installed in neighbouring compartments. This valve is fully reversable and will reset if the rate becomes sufficiently distributed again making it suitable for applications with thermally and hydraulically induced fractures. The target normal operating rates and degree of injection control and trigger rates can be varied by application (Figure 2).

Optimised completion

To validate performance, Tendeka completed full-scale laboratory tests in realistic water injection conditions for a single and multiple FloFuses, defining the characteristics of the valve over a simulated life of well.

Static and dynamic well performance modelling is used to evaluate injection well performance and distribution of water along the wellbore. The FloFuse completion design is optimised for the application by modifying the flow capacity and trigger rates. The well performance for FloFuse is compared against the viable alternative completion designs to enable the value to be quantified.

Maximised ultimate recoveryFloFuse

To manage uncertainty in heterogeneous reservoirs and for the effective management of dynamic changes in injection profiles, Tendeka’s simulation studies have demonstrated that can manage the fluid front more effectively than ICDs with a lower pressure drop, at a fraction of the cost of intelligent completions.

FloFuse provides operators with an autonomous tool to optimise water injection placement and sweep, reducing injected and produced water volumes while maximising oil recovery.