Page 1 of 2Today, industries in the Middle East expect to examine and monitor the status of even the most remote outpost at the push of a button. And, as Pierre Leretz of ABB told Oil Review Middle East, expertise and technology offered by companies like his is helping them do exactly that

"Most of the conversations that we have with our customers today are related to process optimisation. Both upstream and downstream, companies in the region are looking to ensure that they improve efficiencies," said Leretz. "The Middle East markets today offer tremendous opportunities for new investments and deployment of state-of-the-art technologies."

Benefits that include improved asset productivity and energy savings are clearly excellent selling points in a market constrained by falling oil prices and rising exploration costs. Of course Pierre Leretz, President and Region Division Manager, Process Automation at ABB in India, Middle East and Africa, is in a good position to comment on this.

ABB, founded in 1883, is today one of the world's biggest names in power and automation technologies. In the oil and gas market specifically it provides number of solutions for applications to help increase output in upstream, midstream and downstream oil and gas processes.

It's not surprising that companies like ABB are finding a market for their technologies in Middle East oil and gas. While significant finds continue to be announced, reaching such reserves will be a challenge in the future. That challenge, however, will pave the way for the implementation of new technologies.

At the same time oil and gas operators in the region are increasingly concerned about energy efficiency and safety. According to Leretz, it's a scenario that ABB is already geared up for.

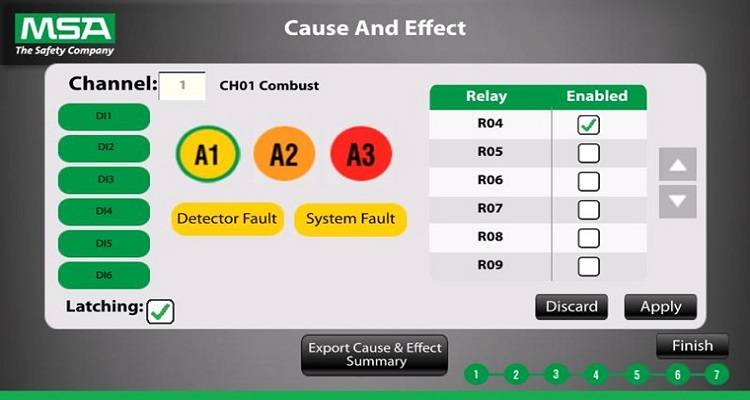

"Security for automation and control systems has gained a lot of attention in the last few years, along with operator effectiveness, which is another crucial area because of its significant contribution to overall plant safety and reliability," he explained, adding, "What we also observe is that the market has significantly moved into ICSS (integrated control and safety systems)."

Many of ABB's oil and gas customers in the region and across the globe are implementing large oil and gas projects that include captive power plants. At the same time they are increasingly looking for integrated instrumentation, control, and electrical solutions to reduce overall cost and implementation time and to increase operational efficiency.

Of course a big concern, and an opportunity for ABB and similar businesses, is risk management. Oil and gas companies need partners who can help mitigate their risk by offering the capability to execute large multi-scope projects with professional project management, a global presence and the ability to guarantee strict compliance to international industry standards. The aim is to ensure timely, high-quality deliveries throughout all project phases, from concept to operation, with a firm focus on health, safety, security and the environment.

"In that regard companies with large projects now demand MAC (Main Automation Contractor) and MEC (Main Electrical Contractor) execution capabilities," noted Leretz. It is no coincidence that he should highlight this trend with ABB already executing the largest MAC project in the world.

These days, in fact, automation is a sine qua non. As Leretz pointed out: "Today, industries in the Middle East expect to examine and monitor the status of even the most remote outpost at the push of a button. Networks make this possible."

Networking technologies now enable the creation of richer and more powerful applications that allow organisations to achieve higher operational efficiency — but that is not all.

"Cyber security, which is a key aspect of networking technologies, has also gained importance in the last few years," Leretz pointed out. "It is not viewed as a one-time activity, but as an integral and continuous part of the project life cycle, from early design and development, through testing and commissioning, to lifetime support service and future adaptations."

All of which is both a challenge and an opportunity for ABB. "Our automation business units are constantly developing applications that allow plants or equipment to run at maximum output, consistently producing high-quality products," Leretz said. "Our industrial IT solutions integrate engineering, operations and maintenance activities on a common technology platform, thus improving overall plant efficiency and safety."

Continues on Page 2...