ADIPEC visitors will get a close look at new Honeywell technologies that are transforming the industry through data insights and analytics

The company will showcase a range of its safety, security and Honeywell Connected Plant solutions – everything from a software-as-a-service data capture platform, to augmented and virtual reality training solutions during the world’s leading oil and gas conference.

Honeywell will demonstrate how its suite of Connected Plant applications can enhance processes to achieve higher performance, safety, and profitability levels.

“In a truly connected world, technology has become about outcomes including driving productivity and increased savings,” said Norm Gilsdorf, president for high growth regions, the Middle East and Russia at Honeywell.

“For the oil and gas industry, it has become crucial to unlocking the incredible knowledge and capabilities of workers by equipping them with the skills and tools needed to optimise knowledge capture, sharing and retention through the use of data,” Gilsdorf added.

ADIPEC visitors will be able to see and experience several technologies that have been launched in 2018 including:

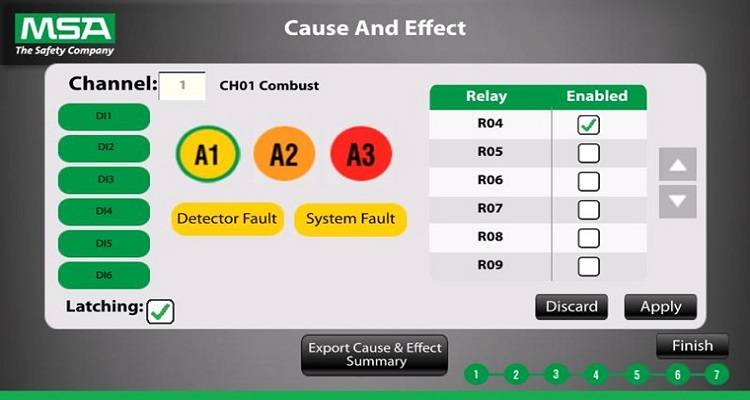

Industrial Fire and Gas – Get hands-on with Honeywell's new industrial fire and gas offerings, featuring SIL2/3 certified controllers, equipped with redundancy and HOT swap, providing high reliability and easy maintenance.

Industrial Safety – Learn how our class-leading gas and smoke detection solutions keep personnel and facilities safe while boosting productivity and lowering compliance and administrative costs. Experience how Honeywell Safety Products provide high quality personal protective equipment and safety gear designed to protect workers across all types of industries.

Immersive Competency – This cloud-based simulation offering uses a combination of augmented reality (AR) and virtual reality (VR) to train plant personnel on critical industrial work activities, empowering them to directly improve plant performance, uptime, reliability and safety.

Thermal IQ – Enables maintenance engineers and plant managers to more effectively monitor and manage their thermal process equipment, minimizing unplanned downtime and maximizing uptime.

Uniformance® Cloud Historian – This software-as-a-service cloud hosting solution for enterprise-wide data capture, visualization and analysis help customers improve asset availability, optimize processes and increase plant uptime.

Asset Performance – Integrates asset and process data for actionable insights to improve asset performance and plant profitability.

Personal Gas Safety – This solution integrates with Honeywell’s leading plant control system to protect workers and speed emergency response in case of hazardous leaks or worker injury.

Intelligent Wearables – This hands-free, wearable technology allows industrial workers to more safely, reliably and efficiently accomplish their tasks in the plant or the field. It uses a head-mounted visual display that responds to voice and brings live data, documents, work procedures, as well as health and safety information into view and can connect field workers with remote experts in real time.

Measurement IQ for Gas - Provides measurement control and meter accuracy by transforming metering operations with 24/7 real-time condition-based monitoring.

Visit Honeywell at ADIPEC 2018 at the US Pavillion located at hall 7, stand 7310.