What contribution is control, switchgear and mechanical engineering making with consistent data from engineering to plant operation? Rittal, Eplan, Cideon and German Edge Cloud discussed these questions with visitors to the SPS in Nuremberg, and explained how they use domain knowledge to promote solutions in the relevant ecosystems

At the SPS 2022, Rittal, Eplan, Cideon and German Edge Cloud (GEC) demonstrated how to connect plants, products and production processes with their respective digital twins for smart production.

“The data is generated in ecosystems that are often still incompletely networked even today. If it is possible to create a complete digital twin for each plant, product and production process and then, in turn, to connect them intelligently, this will be a lever on the way to smart production,” said Markus Asch, CEO Rittal International and Rittal Software Systems. He added, “The SPS is the ideal environment for dialogue with control, switchgear and mechanical engineering professionals in particular – and for answers to the question of how the data from the digital plant twin can also be used to add value in operations. There are great opportunities in this.” To this end, the companies of the Friedhelm Loh Group support their customers with domain knowledge and tangible solutions.

Eplan and Rittal are working with control, switchgear and machine manufacturers to advance the development of the automation twin of machines and systems and make the data usable during operation. Cideon, with its expertise in CAD/CAM, PDM/PLM and product configuration, increases data consistency around the digital product twin. German Edge Cloud uses information from system data for faster networking and to visualise processes as a digital production twin. IIoT-supported production management with the ONCITE Digital Production System then increases production efficiency and flexibility.

Digital from engineering to operations

One focal point at the joint booth of Rittal, Eplan, Cideon and GEC was data consistency along the entire value chain of panel building and switchgear manufacturing – from engineering to supply and from manufacturing to the operational phase of the systems. Panel builders and switchgear manufacturers save time and money in their value-added process with solutions from Eplan and Rittal.

More speed for electrical engineering and supply

The new Eplan Platform 2023 ensures even faster 3D planning with its new graphics engine. An international macro administration to support different standards further accelerates the process. Eplan eStock complements the central article management in the cloud. Eplan Harness proD now supports users with everything involving the cabling of machines. Rittal is speeding up the supply chain with configurators and rapidly deliverable system technology, which now also further integrates the compact AX series as a fully-fledged compact enclosure.

New machines and software for the workshop

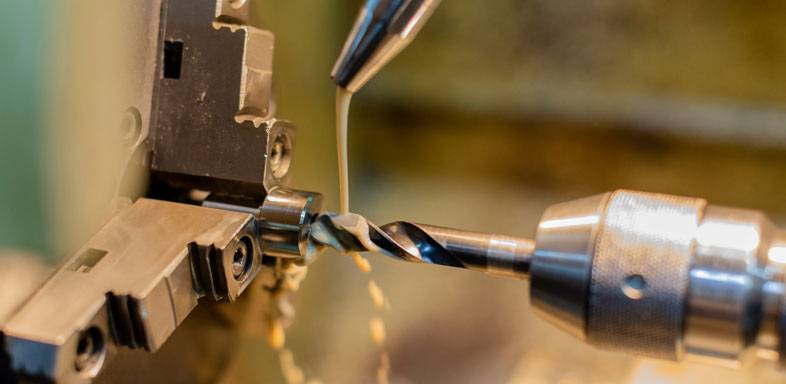

The WT C10 Wire Terminal, a highlight of the Rittal trade fair, is a new version of the fully automatic wire processing machine, processing wires ten times faster than by hand. The development offers many improvements, for example a modular approach to the supply and output of wires with a new wire magazine system and quickly exchangeable feed blocks. The Wire Terminal’s new software architecture ensures seamless integration into the workflow of the RiPanel Processing Centre.

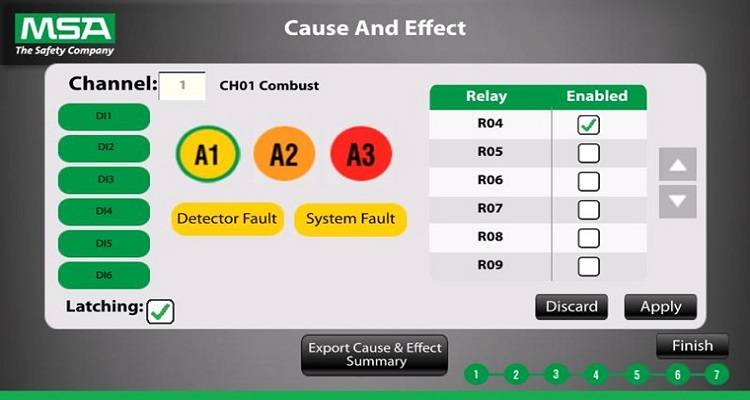

Eplan’s ‘Smart Mounting’ software now also visualises the mechanical and electrical components used in enclosure construction, while Eplan Smart Wiring guides you through the cabling.

IIoT data for manufacturing management

The operational phase of the systems involves more than just maintenance benefits through system data in the ePocket digital wiring plan pocket, or 75% energy savings with new Blue e+ cooling units or smart services. The ONCITE Digital Production System combines formerly separate core features of digital production in a system with a flexible architecture: agile production management with MES and MOM functions, industrial IoT as a database and low-code development for simple application development. On top of this, edge computing meets all demands regarding sovereignty in data processing.