US-based General Atomics Electromagnetic Systems (GA-EMS) Group has received an order for a 180-module Gulftronic electrostatic separator to be installed at the Oman’s Sohar Refinery

The Gulftronic system will replace an existing mechanical filtration system that was installed in 2008 at the refinery to meet the plant’s operational demand.

Modern refineries rely on residual fluidised catalytic crackers (RFCC) to convert heavy crude oil into gas products. The conversion process creates slurry oil/decant oil, a by-product containing catalyst fines.

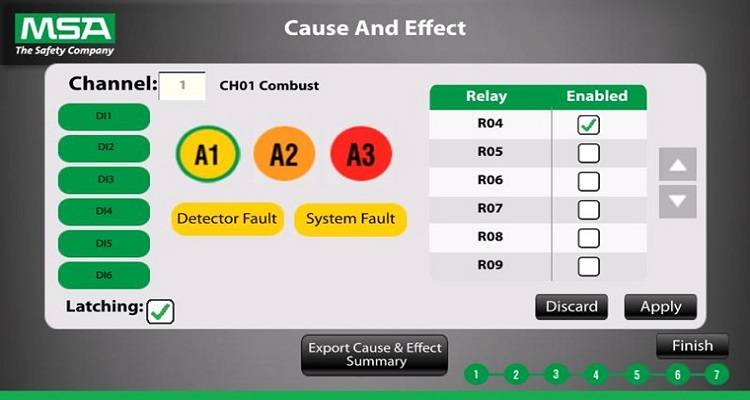

Through a unique electrostatic process, Gulftronic separators capture and remove all solids from the process stream, resulting in higher value clarified oil products, less downstream contamination and significantly reduced maintenance requirements.

Vivek Lall, vice-president, global commercial strategic development at GA-EMS, said, “Our shared goal is to help Orpic reduce maintenance costs and downtime, and to meet their requirements for oil clarity and increased production capacity to maximise the refinery’s revenue potential.

“Mechanical filtration systems allow fine particles to escape capture, causing blockages, buildup in the filters and a higher incidence of contamination, all of which result in increased downtime and elevated maintenance costs. Gulftronic electrostatic separators provide clarity below 100 ppm and are impervious to fouling, which helps refineries improve yields and profit margins.”

Kamil al Shanfari, general manager at Sohar refinery, stated, “Orpic is one of the largest and most rapidly growing businesses in the Middle East oil industry. Our strategic growth projects – Sohar Refinery Improvement Project (SRIP), Muscat Sohar Product Pipeline (MSPP) and Liwa Plastics Industries Complex (LPIC) – are in line with our plan to add value to the oil and gas molecules produced in Oman. The focus is on a higher standard of efficiency, lower costs, minimising safety and security hazards, and reducing environmental impacts.”

He added that with the installation of the Gulftronic electrostatic separator, the refinery will be able to process more high value products, reduce maintenance costs and, thereby, expand the business into the future by further maximising the value of Omani crude oil.